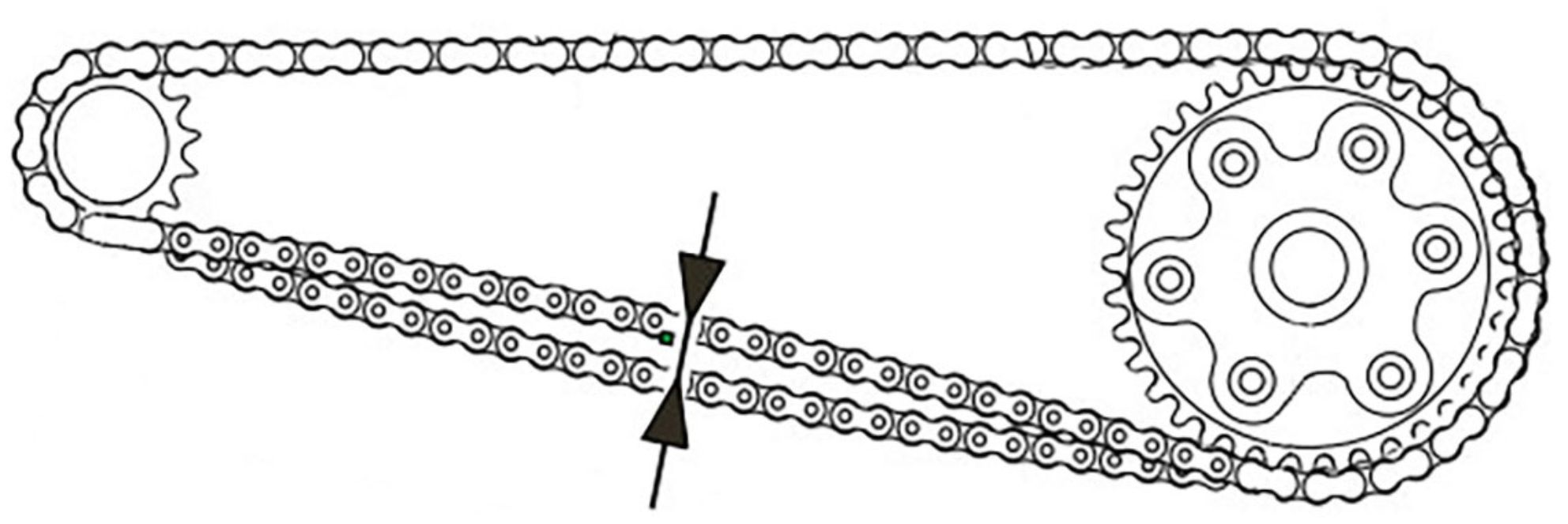

Proper chain tension is critical in achieving maximum service life, as excessive tension can cause accelerated wear or chain overload, while excessive slack can cause rough chain operation and possibly result in the chain skipping a sprocket tooth, and possibly catastrophic failure.

Ideal chain tension for various drives

For the majority of slow and medium-speed drives, the total mid-span movement in the slack span of the chain should be approximately 4-6% of the drive’s center distance. For drives operating at high speeds, impulse, or reversing loads, the total mid-span movement should be reduced to 2-3% of the center distance.

Drives with vertical centers should also be adjusted to a smaller percentage.

Maintaining appropriate chain tension

One challenge is maintaining the appropriate level of chain tension over the life of the chain. To avoid having to manually maintain the position of sprockets and idlers, spring-loaded chain tensioners which incorporate travel can maintain consistent and appropriate levels of chain tension as the chain "stretches". The right and consistent chain tension will maximise the life of chains and sprockets, while also keeping noise to a minimum, as well as reducing the risk of chains skipping.

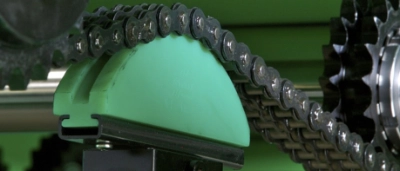

The murtfeldt Kunststoffe Spann Box range

The Murtfeldt Kunststoffe Spann Box range is a spring-loaded chain tensioner that is a proven product that has been used worldwide to provide chain tensioning solutions. With options that have adjustable spring-loaded tensions, they are versatile, while also being maintenance-free.

.png)

Murtfeldt is proudly represented in Australia and New Zealand by Dotmar Engineering Plastics, which has five branches in Australia, plus an additional three branches in New Zealand.

Qualified engineers can also assist with selecting the most appropriate Spann Box size to suit your chain and application.