With over 50 years of expertise in the Food and Beverage Industry, Dotmar is the most established and premier supplier in the ANZ region. Our extensive range of conveyor parts and engineering thermoplastics, sourced from global leaders, ensures unmatched quality. Supported by our state-of-the-art machining facilities and supplementary services, partnering with Dotmar guarantees not only superior products but also effective risk mitigation for your production processes.

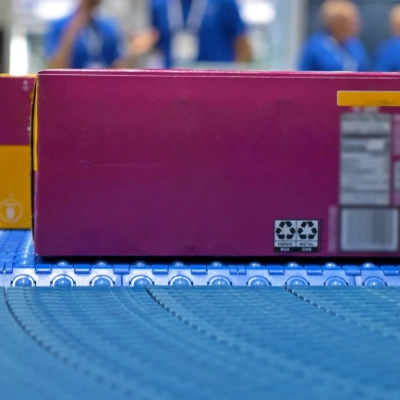

Dotmar understands the needs of beverage producers at every stage of the production process. From sterilising and rinsing to filling, capping, labelling, and packaging, Dotmar’s comprehensive portfolio ensures your operation runs smoothly with the conveyor coverage you need backed by the service you deserve.

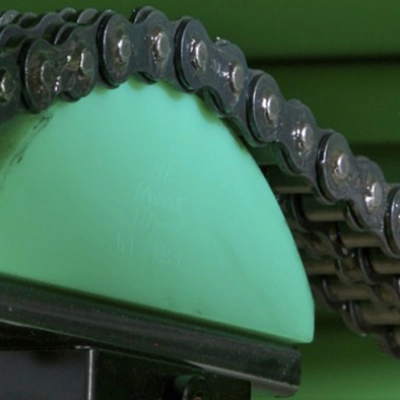

We offer the widest selection of finished conveyor parts from top brands such as Systemplast, Regal Rexnord, and Cambridge.

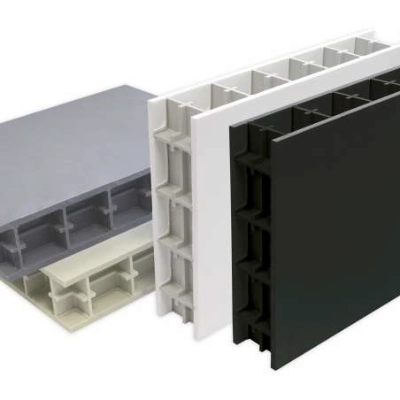

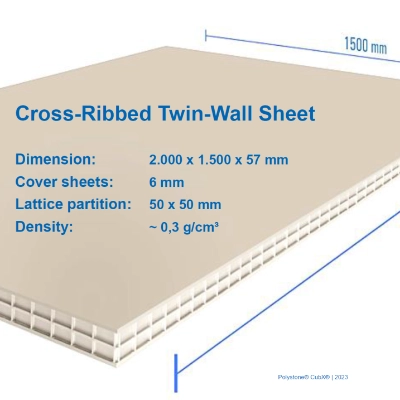

Our range of productas for the bottle and beverage industries includes conveyor belting, conveyor components, flat top chain, UHMWPE (Polystone) conveyor curves, and PTFE coated glass cloth non-stick belting (Taconic)

Whether you are replacing, retrofitting, or specifying products for new lines, our team ensures you have complete coverage.

Featured applications

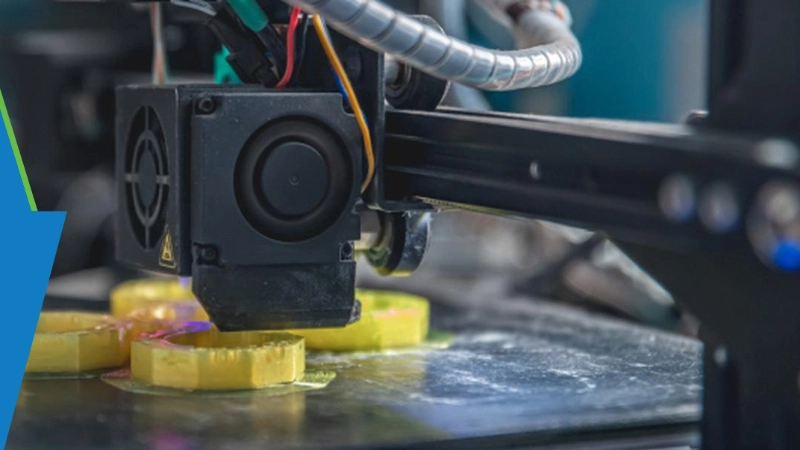

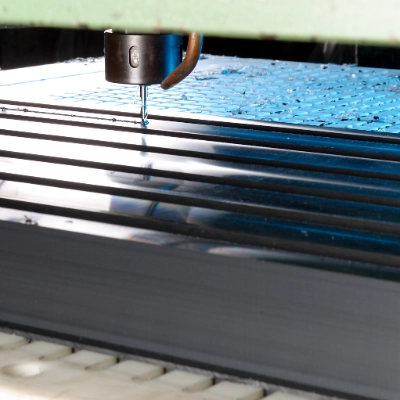

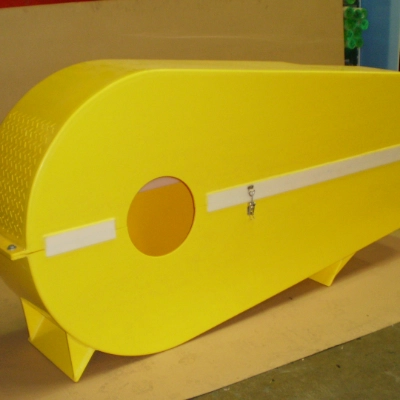

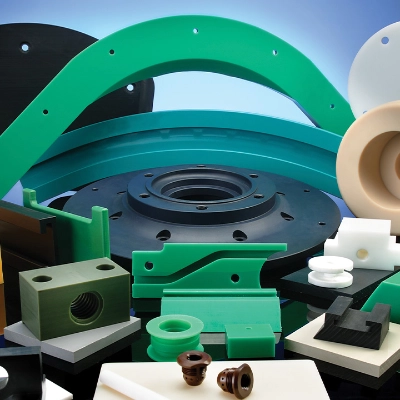

Dotmar specialises in creating custom machined parts tailored for the beverage processing and packaging industry. Leveraging our extensive range of engineering plastics and our comprehensive inventory of conveyor parts from leading brands, we ensure you receive the right parts exactly when needed. By collaborating closely with your team, we minimise downtime through maintenance scheduling and mitigate production line risks with thorough audits.

Some of the parts we can machine include:

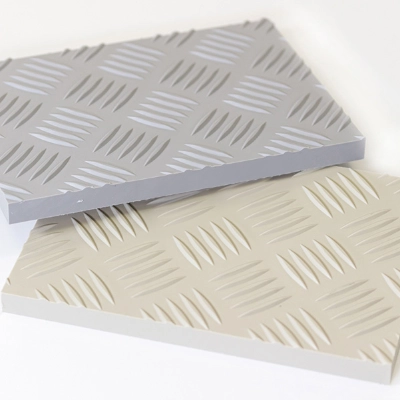

Plastic Conveyor Curves

- Materials: Polystone UHMWPE, Nolu SR, Sustaglide

- Benefits: Designed for operational efficiency and exceptional wear resistance, making them ideal for the rigorous demands of beverage processing and packaging.

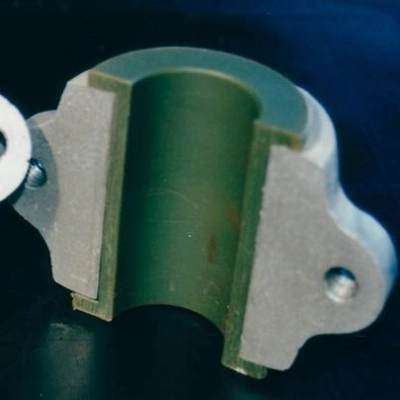

Plastic Feed Scrolls

- Material: Polystone (UHMWPE) rod

- Benefits: Preferred by maintenance engineers for its high resistance to stress cracking and noise reduction features, ensuring smooth and reliable operation in bottling and canning lines.

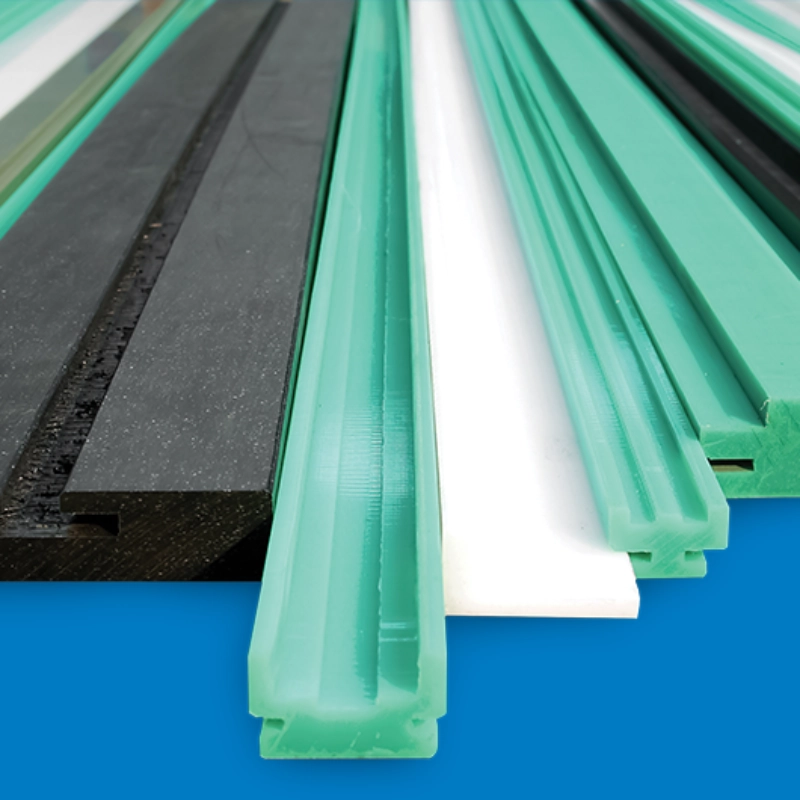

Profiles & Wear Strips

- Materials: Machined and extruded Polystone (UHMWPE), Sustaglide, Acetal

- Benefits: Ideal for chain guides and plastic wear strip applications, these components reduce vibration and friction, offering superior wear resistance compared to stainless steel wear strips, thereby enhancing the durability and efficiency of your beverage production lines.

Consult our highly experienced product specialists for the best recommendations on optimal product selection tailored to the unique needs of the beverage processing and packaging industry.

With the largest stock of conveyor products, widest coverage, and partnerships with world leading brands, Dotmar ensures access to the right parts at the right time. Backed by the most experienced personnel and exceptional supporting services, Dotmar stands as the most established and integrated solution provider in the industry, guaranteeing unmatched support across all operational aspects.

Line Audits and Process Optimisation

We collaborate with you during planned maintenance shutdowns to accomplish the following goals:

1. Conduct a thorough inventory of conveyor and engineering plastic products, utilising a traffic light system for transparent condition assessment and minimising operational disruptions.

2. Identify opportunities for efficiency improvements through product upgrades and replacements.

3. Identify critical spare parts necessary for uninterrupted operations.

4. Offer retrofitting solutions for production lines, including dry-run or lube-less options.

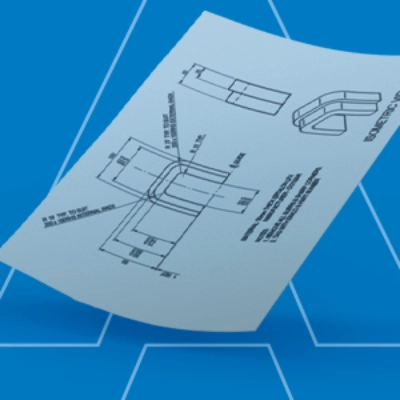

5. Create detailed drawings for customised OE parts based on specific requirements.

Engineering Consultation

Our experienced team of industry experts and qualified engineers are able to provide the following services:

• Provide product specifications for new production lines and conveyor systems.

• Perform conveyor calculations for troubleshooting and resolving conveyor-related issues.

• Conduct bearing calculations and other engineering qualification and validation.

• Product Identification: identify, design and manufacture replacement parts for discontinued products to ensure seamless operation.

Download our brochures for further details