Vibratory springs are a critical component in conveyors, screens, feeders and sorting equipment, yet they are often overlooked until performance issues arise. Traditionally made from steel, springs serve to support dynamic motion, control resonant behaviour and isolate vibratory forces from supporting structures. Over the past decades, advanced fibre composite materials have transformed this technology, offering significant performance advantages for demanding industrial applications.

In this Insight, we explore what fibre composite vibratory springs are, why they are increasingly specified in modern machinery, and how material selection affects performance and reliability.

What are Fibre Composite Vibratory Springs?

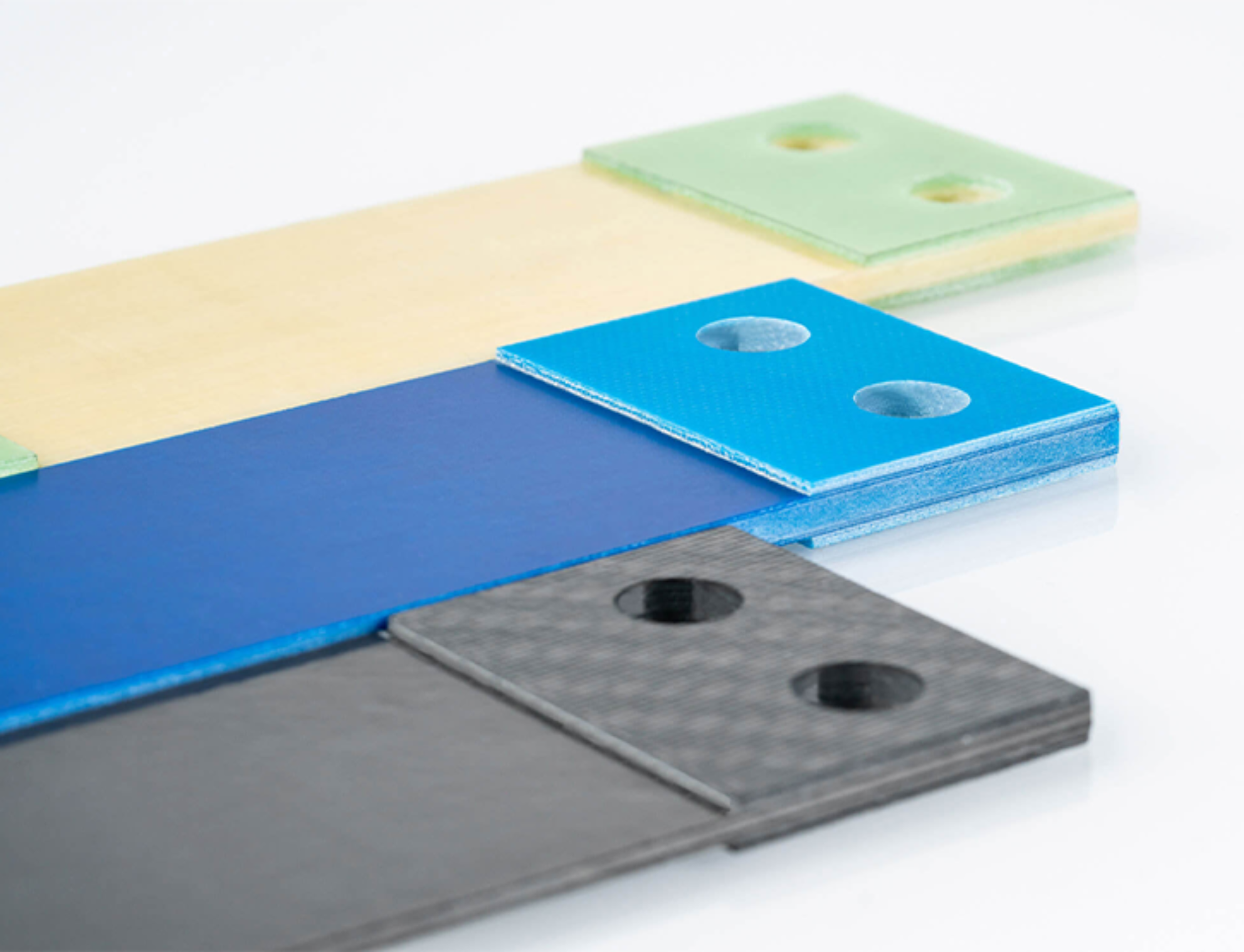

Fibre composite vibratory springs are engineered spring elements made from fibres — typically glass or carbon — embedded in a polymer resin matrix such as epoxy. These composites are processed into layered “leaf” springs that flex under load, as part of a machine’s vibratory motion.

Unlike traditional metal springs, composite springs deliver high fatigue resistance, excellent damping behaviour and predictable dynamic response over long service life. They are manufactured with unidirectional fibre reinforcement, meaning mechanical properties can be tailored to specific application needs by orienting the fibres relative to the load direction.

prause-durotec.de

The S-Ply® range exemplifies this technology, with materials such as S-Ply Yellow, S-Ply Yellow HT, S-Ply Blue, S-Ply Carbon and S-Ply Carbon Blue engineered to meet differing environmental and performance requirements.

Why Fibre Composite Springs Bring Performance Advantages

Fibre composite springs have distinct performance benefits compared to steel, especially in high-cycle vibratory applications:

Superior Fatigue Resistance

Composite fibres maintain structural integrity over millions of cycles without cracking or work hardening, a common failure mode for metal springs under continuous vibration.

Tailored Dynamic Response

Fibre orientation and composite layering allow engineers to design springs with specific stiffness, natural frequency and damping characteristics, optimising system resonance behaviour.

High Elastic Energy Storage

Materials like S-Ply® exhibit a high specific spring effect and balanced dynamic behaviour, enabling efficient energy storage and release.

Lightweight and Corrosion-Resistant

Composites weigh considerably less than steel and are inherently resistant to moisture, chemicals and corrosion — ideal in food, chemical and wet environments.

Temperature-Capable Options

High-temperature variants such as S-Ply Yellow HT extend composite performance into elevated temperature applications without compromising spring behaviour.

The S-Ply® Range — Designed for Vibratory Performance

Dotmar’s supply offering includes a comprehensive range of composite vibratory materials suited to a broad spectrum of industrial conditions:

- S-Ply Yellow – Standard composite spring material with balanced stiffness and energy storage properties.

- S-Ply Yellow HT – Heat-resistant version capable of reliable performance in elevated temperature environments.

- S-Ply Blue – Food-industry compatible material with antimicrobial properties, food safety regulatory compliance, and visually detectable in food stuffs.

- S-Ply Carbon – High modulus carbon fibre composite for applications requiring higher stiffness and load capacity.

- S-Ply Carbon Blue – Food-grade carbon composite combining strength with food safety regulatory compliance.

Each material variant is engineered to balance mechanical strength, fatigue life and environmental suitability, allowing designers to optimise solutions for conveyors, screens, feeders and sorting equipment.

S-Ply Range

When Composite Springs Make the Difference

Fibre composite springs are particularly valuable in applications where:

• Large numbers of load cycles accelerate metal spring fatigue

• Corrosion or humidity compromise conventional springs

• Precise vibration tuning is required for repeatable material handling

• Hygiene standards demand food-safe materials

• Weight reduction improves dynamic responsiveness

In vibratory systems operating at or near resonance, spring performance directly influences throughput, energy consumption and machine longevity. Composite springs help achieve stable, efficient vibration behaviour with minimal maintenance.