Reducing Plant Hazards with Plastic Machine Guarding

A plastic guard is a physical barrier that can perform several functions including

- Preventing contact with moving parts or controlling access to dangerous areas of plant.

- Screening harmful emissions, for example radiation.

- Minimising noise

- Preventing ejected parts or off-cuts from striking people.

Plastic fabricated guards that Dotmar provide materials for generally take one of the following forms

- Fixed & interlocked guards – these are not permanent in that they can be removed for access in the case of cleaning, maintenance or setting up equipment.

- Tunnel guards – used typically when product being processed needs to flow through a machine.

- Fences & protection by distance – prevent persons accessing a dangerous zone.

- Other types of guards, include permanent, adjustable and self-closing.

Which Plastic Should be Used?

The guard or barrier function will generally dictate the most appropriate plastic material to be used.

Function 1 – Preventing Contact with Moving Parts

A common application where preventing contact with moving parts is a belt drive between a motor and a pump, which requires a fixed or interlocked type of guard that is not permanent, so it can be removed for maintenance.

Traditionally these guards have been made from sheet metal and then painted in a safety yellow to bring attention to the hazard or potentially dangerous equipment. Often these guards rust and require re-painting to ensure that they are visible and safe.

The most suitable plastic for this type of guard is “Polystone 300 Yellow UV”. This material is easily fabricated, using CNC routers to machine the individual panels, welding to form the guard, and fasteners or a toggle clamp to hold the two halves together.

Benefits of Polystone 300 Yellow UV vs sheet metal

• Corrosion and chemical resistance

• Permanently yellow, i.e. no re-painting required

• Lightweight

• Better noise suppression

Function 2: Screening Harmful Emission – Neutron Radiation

Neutron radiation is shielded by materials or substances that contain hydrogen, such as water and polyethylene.

Specially formulated grades of plastic have been developed called “Polystone D Nuclear” and “Polystone M Nuclear”, with a hydrogen content of 13 - 14 %, one of the highest hydrogen contents of any solid material for neutron shielding available on the market.

Benefits of Polystone D Nuclear & Polystone M Nuclear

• High resistance against high-energy radiation for extremely long service life

• Light weight which facilitates easy handling during processing and construction

• Easy processing utilising traditional techniques such as sawing, cutting, milling and gluing.

Function 3: Minimising Noise

A noise hazard is a situation where exposure to excessively loud and/or prolonged noise levels poses a potential risk to human health, often leading to hearing damage.

There are many ways to protect workers from the hazard of noise, with one potential solution being to encase the noisy equipment within an enclosure to suppress the sound that is experienced by people within the vicinity.

Foamlite is a lightweight sturdy material that can be easily fabricated into a guard to enclose a noisy piece of equipment.

Benefits of Foamlite

• Easily fabricated

• Light weight – lighter than solid sheet

• UV resistant for outdoor use.

• Embossed texture surface finish for an aesthetically pleasing appearance, and aiding scratch resistance.

Function 4: Preventing Ejected Parts from Striking People

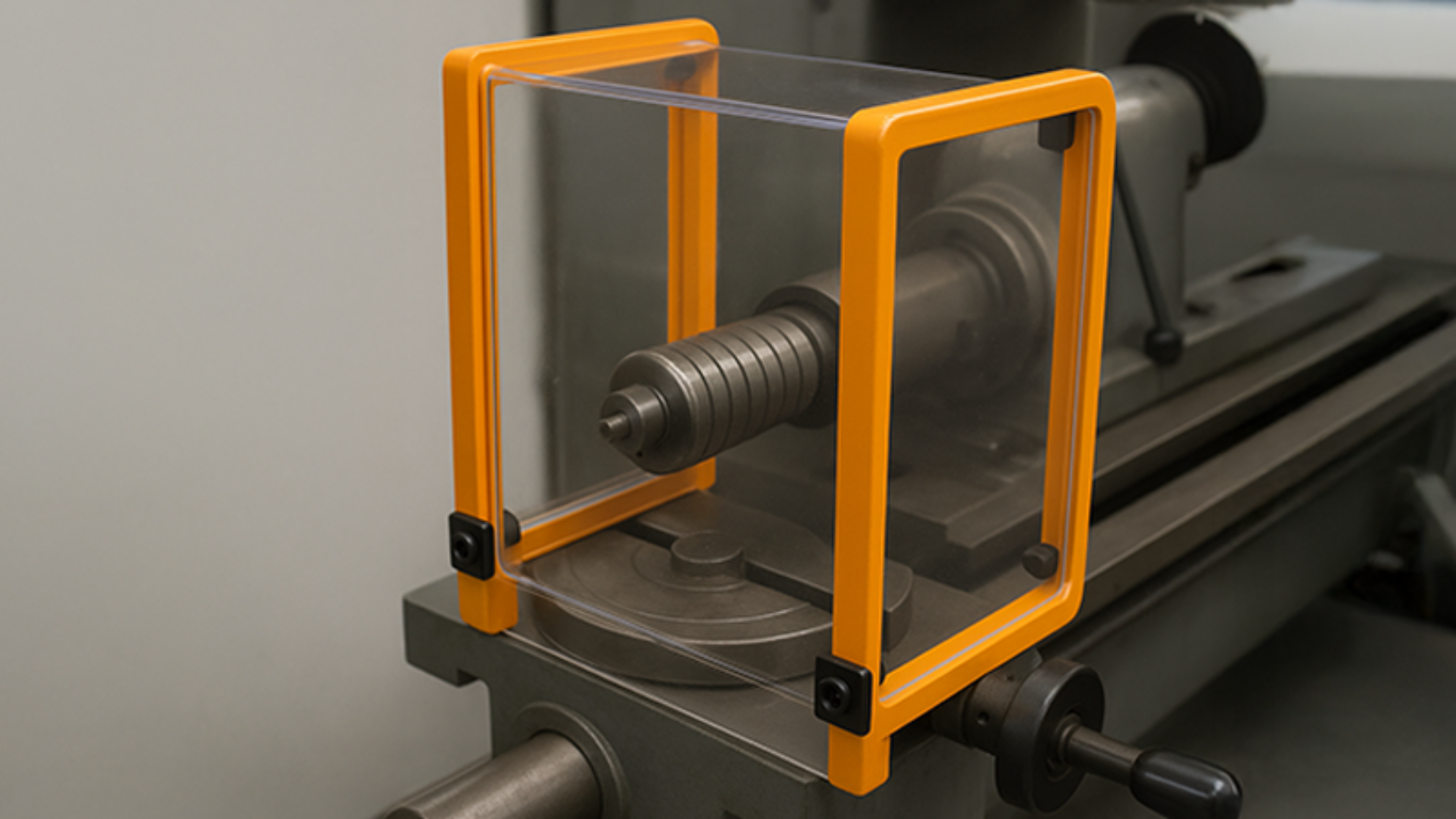

A typical application where a machine guard is required to prevent a person being struck by an ejected part is for machining equipment, such as a CNC router or milling machine.

In these applications it is generally essential for the operator to stay close and be about to see the machine working, to carry out the machining function. Therefore, a see through and extremely impact resistance material is required. This is when the well-known material, polycarbonate is utilised.

Polycarbonate is 250 times more impact resistant than glass, and 30-40 times more impact resistant than acrylic.

Benefits of Polycarbonate

• See through – 88% light transmission

• Extremely impact resistant

• Easily machined

• Can be bent and thermoformed for more complex shapes

• UV Resistant