We often are asked about the compression strength of our engineering plastics, i.e. what load can a given plastic take. As engineers we like to be able to give a definite number, but when it comes to the compression strength of engineering thermoplastics this is not always possible, as factors can vary the materials capability to withstand a force. We often are asked about the compression strength of our engineering plastics, i.e. what load can a given plastic take.

How are plastics tested for their compression strength?

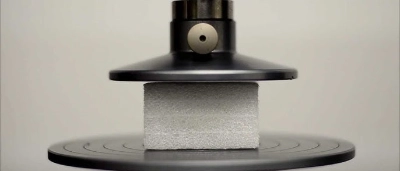

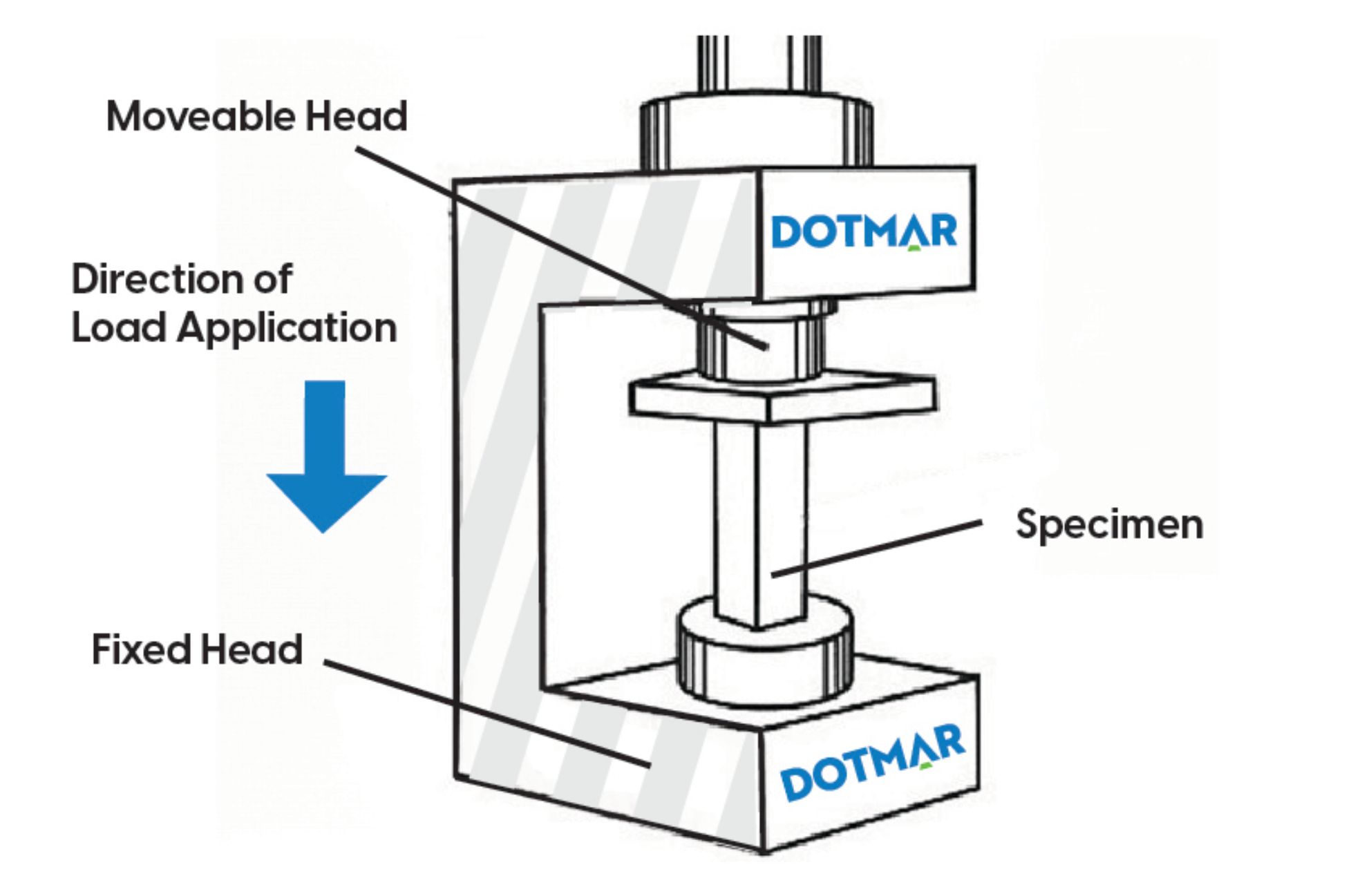

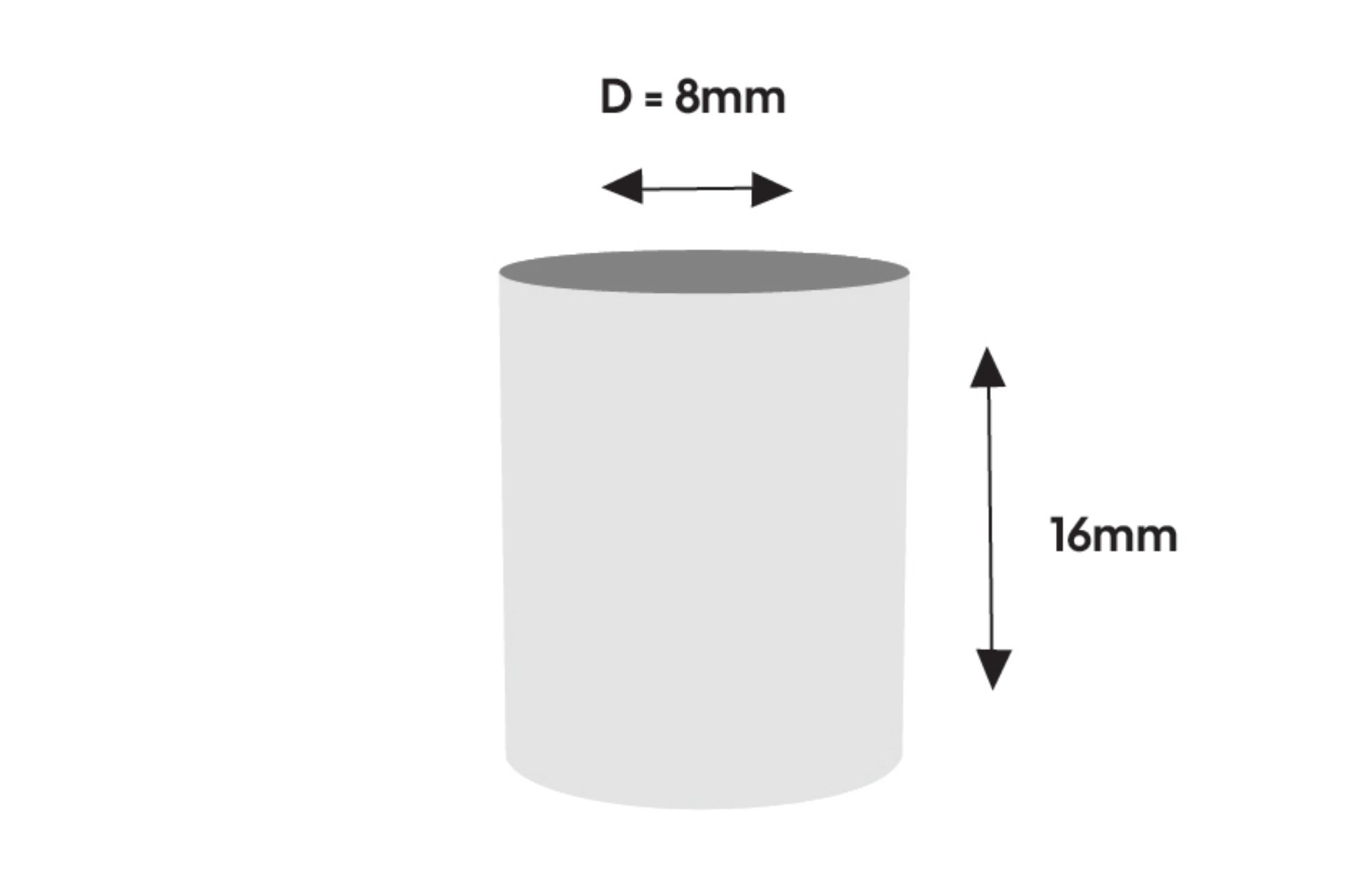

A compression test specimen (Ø8 x 16mm) is placed between two metal discs on a compression testing machine. The test piece is loaded with a constant deformation rate (speed of squashing) until a certain strain (percentage of squash) is reached. A force/deformation or stress/strain graph is recorded from which compressive properties then are derived.

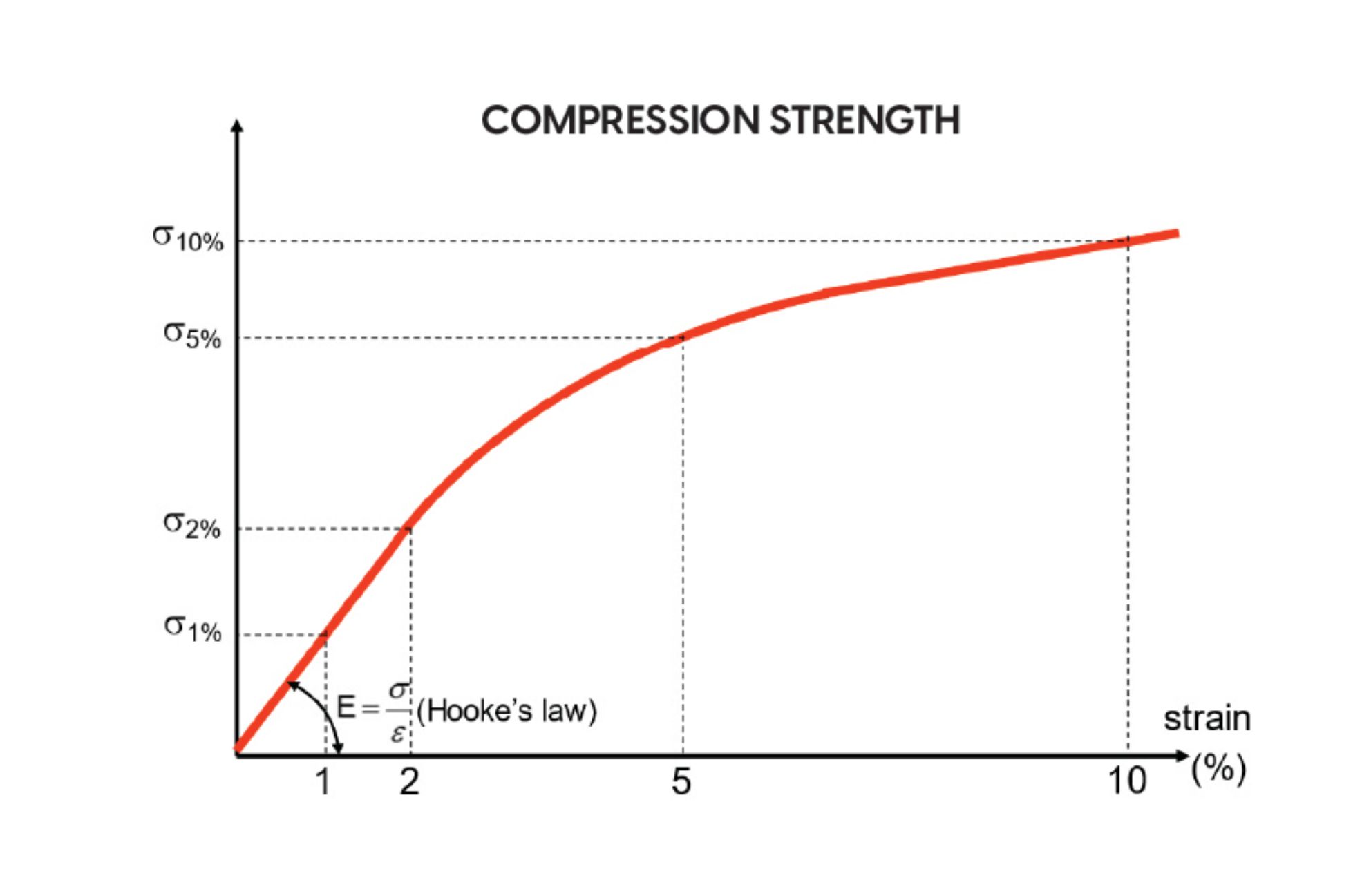

Generally, since thermoplastics don’t have a catastrophic failure point in compression, material technical data sheets contain the values for 1, 2 and 5% strain, as per the below example.

| Compressive Stregth 1 /2 / 5 % Nominal Strain | ISO 604 (10) | MPa | 38/75/140 |

|---|---|---|---|

| Compressive Strength |

Question: Does this compression strength relate directly to your part?

Answer: No, unless your part has the same ratios (diameter to length) as the test specimen.

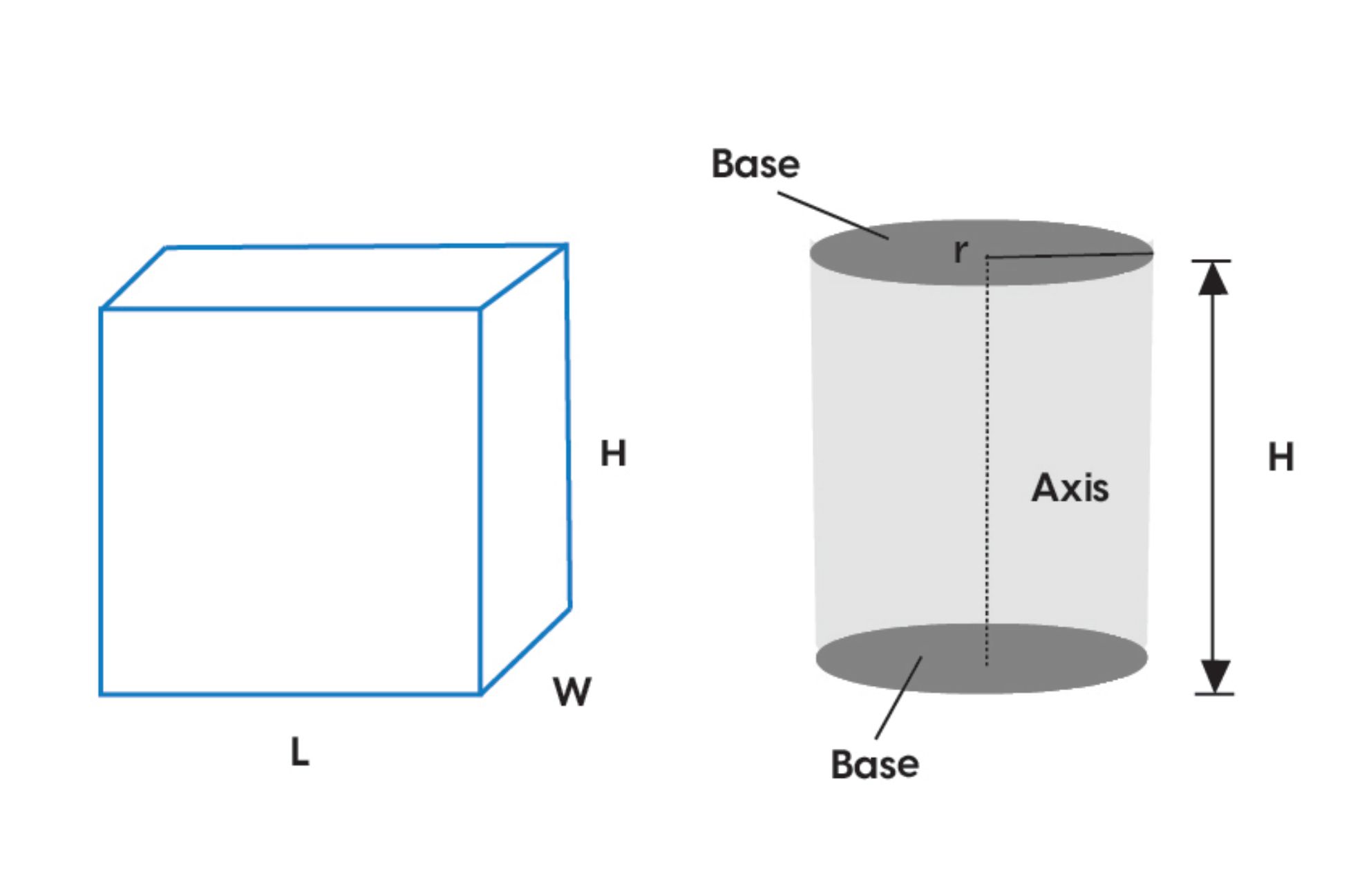

This is due to the “Shape Factor,” which is the ratio between the area of the perimeter of the part and the area of the top and bottom surfaces. Large flat parts will deform less under the same load compared to taller parts.

Other factors that will affect the deformation and load-carrying capacity include temperature and duration of load

Dotmar engineers can help determine the most appropriate material for applications and provide the material properties required for your Finite Element Analysis.

For more information, contact us here