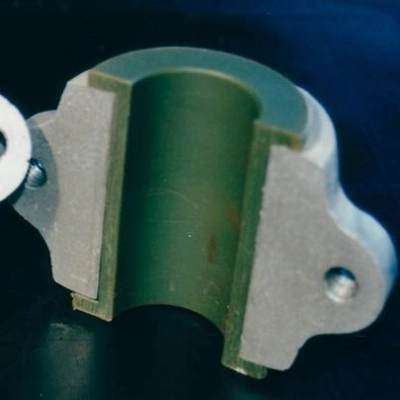

What is a Plastic Bellow Joint?

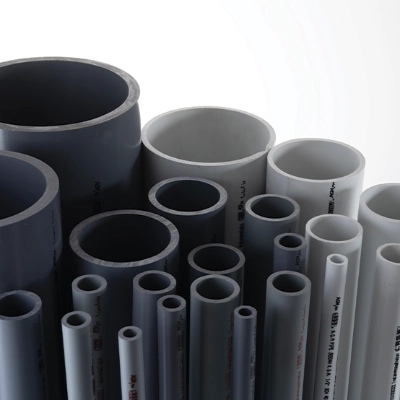

A flexible bellow joint, or expansion joint, is a device used in engineering and piping systems to absorb thermal expansion or contraction, isolate vibrations, and compensate for misalignments or movements. These joints are commonly found in pipelines, ductwork, and other systems where flexibility is required, and helps prevent damage to the piping or equipment by allowing for controlled movement. Flexible bellow joints are crucial in applications where rigid connections might be prone to failure due to thermal stresses or other dynamic forces.

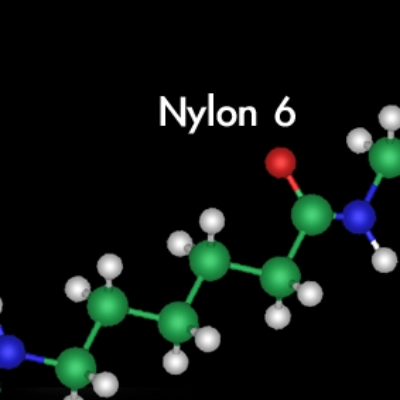

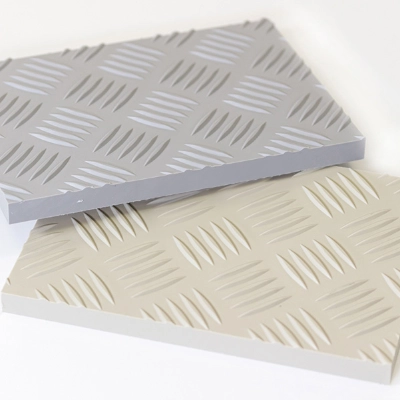

Typically made of Tetron S or Tetco V, these materials allow the joint to flex and absorb movements without transmitting excessive forces or stresses to the connected components.

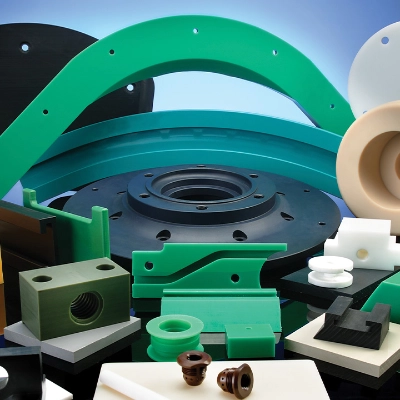

Benefits of machined plastic bellow joints

- Corrosion and chemical resistance – Tetron S & Tetco V have superior corrosion and chemical resistance to other materials that can be used for bellow joints, such as elastomers and metals.

- Cost effective – machining plastic bellow joints do not need any initial tooling, therefore is cost effective for short production runs, as well as higher production runs on the appropriate CNC machining equipment.

- Lightweight – This is advantageous in weight sensitive applications, as well as making installation easier for larger joints.

- Noise dampening – Plastics suppress noise better than metal bellow joints, which benefit work health and safety issues.