What is a Conveyor Skirt?

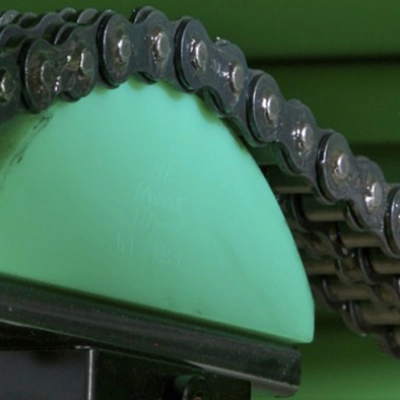

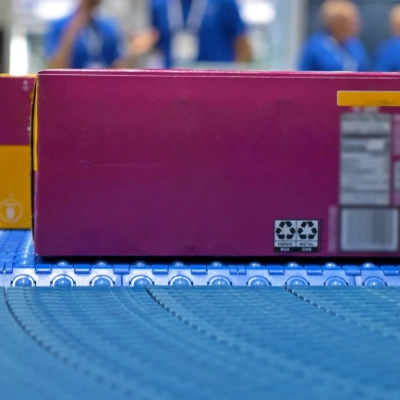

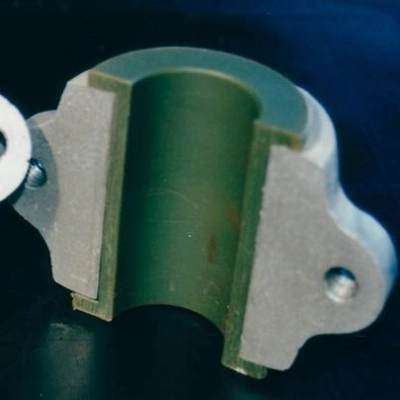

A conveyor skirt is an essential component in conveyor systems designed to contain material on a conveyor belt and preventing spillage. Installed along the sides of the conveyor belt. Its primary function is to create a seal between the moving belt and the surrounding structure, such as the conveyor framework. This seal helps in controlling the movement of material, minimizing spillage, and reducing the escape of dust or fine particles.

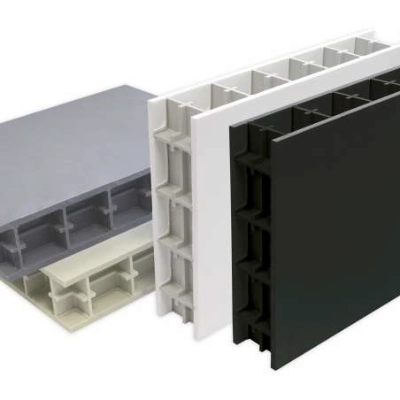

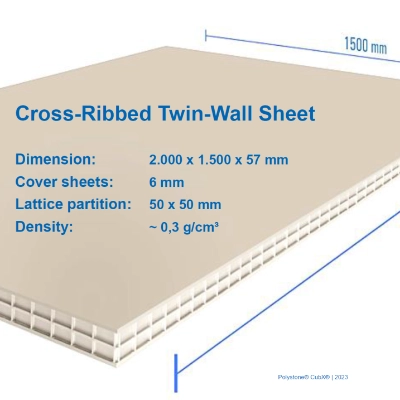

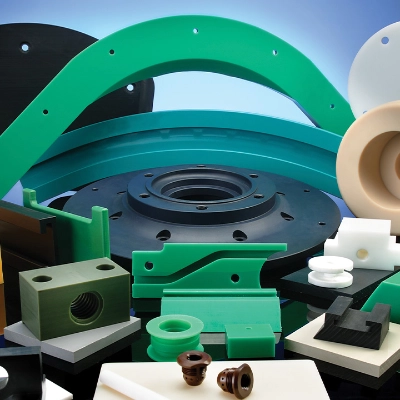

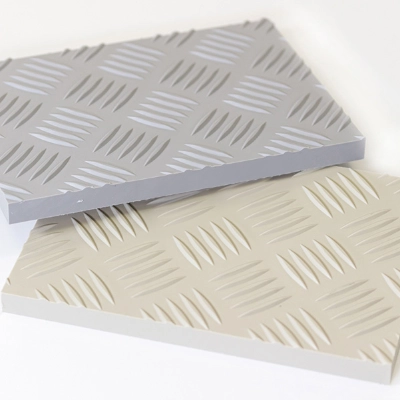

The skirt is usually made of rubber, polyurethane, Polystone 300 and Polystone 7000 for conveyor belts with belt speeds up to 3-4 m/s. For higher belt speeds, a specially formulated material, Ticomp HVM, when the traditional materials will fail or have unsatisfactorily short service life. Conveyor skirts come in various designs and sizes to suit different conveyor systems and materials being transported. They play a critical role in enhancing the efficiency of conveyor systems by ensuring that conveyed materials stay on the belt and within the intended transfer path.

Benefits of Plastic Conveyor Skirt over Elastomers (Rubber & Polyurethane)

- Low Friction – Polystone 300 and Ticomp HVM provide a lower co-efficient of friction compared to rubbers and polyurethane. This reduces the energy to drive the conveyor belt, therefore lowering energy consumption and running costs.

- High Belt Speeds – Higher throughput and production can be achieved with Ticomp HVM, where it has successfully been used with belt speeds of 6 m/s, while rubbers and polyurethane tend to have a belt speed limit of 3-4 m/s.

- Reduced wear – Ticomp HVM better wear resistance, which is particularly noticeable at higher belt speeds compared to traditional conveyor skirt materials, such as rubber, polyurethane and HDPE.

- Cost – Polystone 300 and Polystone 7000 is a lower cost material compared to elastomeric materials.

Dotmar has qualified engineers that can provide direct support with conveyer skirt designs, including conducting calculations and reports.