What is an Industrial Plastic Cutting Board?

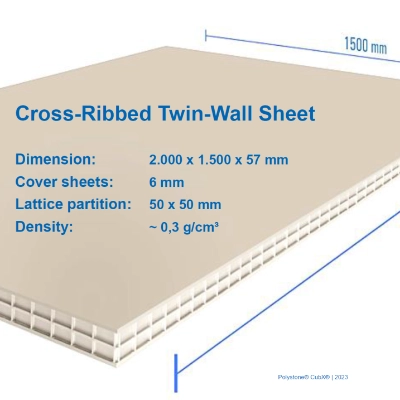

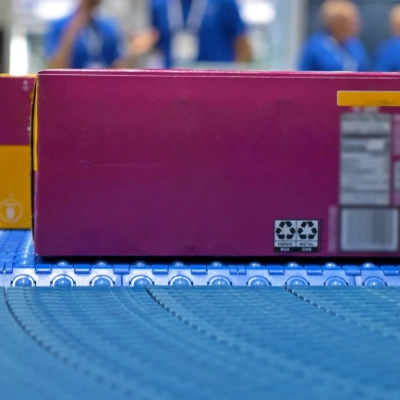

An industrial cutting board refers to a specialised cutting surface used in industrial settings, such as manufacturing, fabrication, or commercial and large-scale food production facilities. These cutting boards are designed to withstand heavy-duty use, frequent cutting, and are often made from durable materials that can endure rigorous conditions.

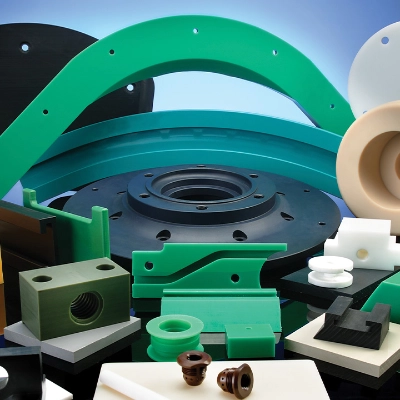

Benefits of high-quality industrial plastics over commodity plastics and other materials

- Plastics offer easily cleanable and hygienic longevity compared to wood and less cut resistant plastics, that can harbor bacteria growth. Plastics are not affected by cutting agents, as well as not absorbing the chemicals, and easily rinsed.

- Zero moisture abosption.

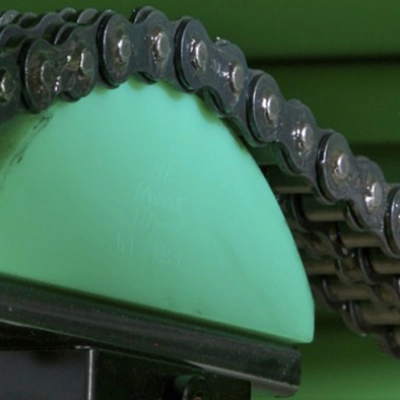

- Compared to hard cutting board materials (glass, metal and harder polymers), high quality plastics maximise knife and blade life, i.e. staying sharp longer.

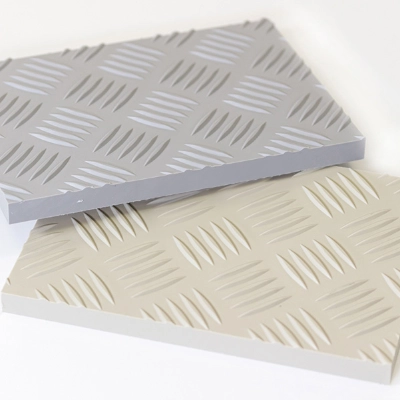

- Colour options – to eliminate cross-contamination between food stuffs, coloured cutting boards can be used to identify and segregate cutting boards.

- White – baked goods or general

- Green – Fruit and vegetables

- Red – raw meat

- Brown – cooked meats and leftovers

- Blue – seafood and fish

- Yellow - Poultry

- Low Friction – This allows for easy and quick sliding and rotating items to aid efficient operations, and minimising blemishing goods.

- Cost effective – in addition to having a low up front cost, they further extend their commercial benefit by providing a long service life.

- Compliance – meet health codes and standards.

Dotmar has qualified engineers that can provide direct support with material selections for cutting boards.