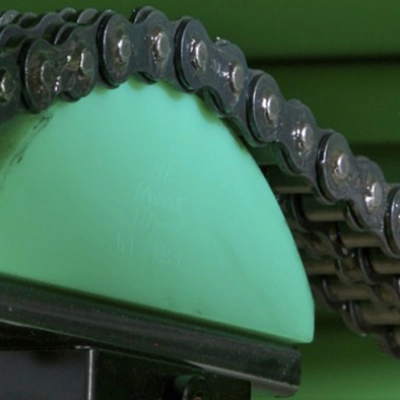

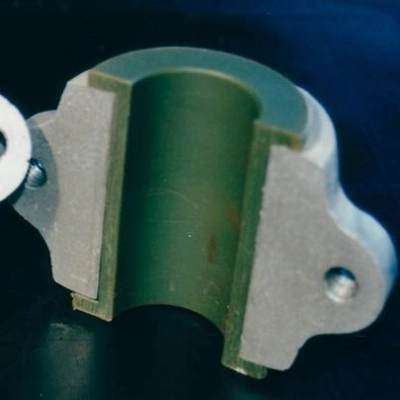

What is a J-Bar?

Also known as J-Hooks, a J-Bar is a conveyor chain attachment that is used to convey lumber in a timber mill. The design is such that it will flex in the event of “fouling” or a “jam” occurring. The intention is the J-Bar will flex or deform as a sacrifice part to minimize the potential other another more costly part failing, as well as minimising the likelihood of production down-time.

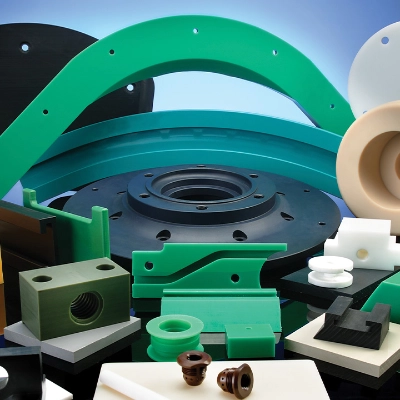

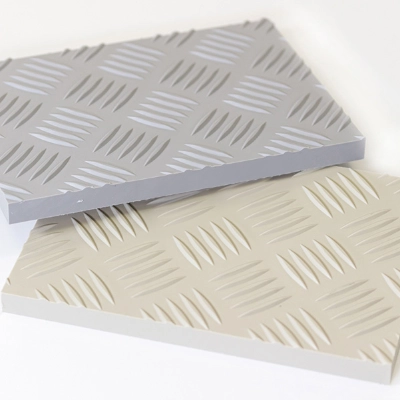

Benefits of Plastic J-Bars

- Reduced Damage - Plastic J-Bars are less likely to cause damage to the surface of the timber compared to metal hooks. This is particularly important when handling finished timbers where surface damage can affect the appearance or quality of the final product.

- Sacrificial – plastic J-Bars are ideal as a sacrificial part in the even of a “jam” in the conveyor, minimising the chance of another high-cost component breaking, that is more difficult to replace and resulting in more down-time.

- Corrosion Resistance - Plastic hooks are not susceptible to rust or corrosion, unlike metal hooks. This makes them suitable for use in environments with high humidity or exposure to moisture, such as sawmills where water or wood sap may be present.

- Lightweight - Plastic J-Bars are typically lighter than their metal counterparts, which can make them easier to handle and manipulate during operation. This can contribute to improved worker safety and reduced fatigue during repetitive lifting tasks.

- Cost-Effective - Plastic J-Bars are cost-effective to manufacture than metal hooks, resulting in potential cost savings for the sawmill operation. Additionally, their durability and resistance to corrosion can contribute to longer service life, reducing the need for frequent replacement.

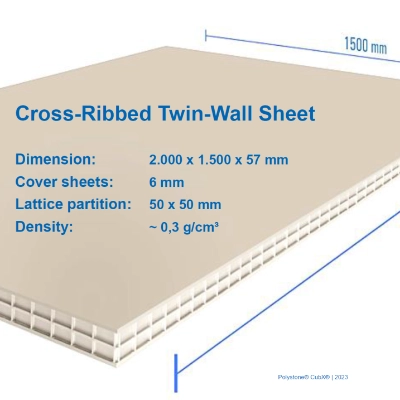

- Customisation - Plastic J-Bars can be easily machined into different shapes and sizes to suit specific applications or preferences. This allows for customisation according to the requirements of the sawmill operation, such as accommodating different timber sizes.

Dotmar has qualified engineers that can provide direct support with plastic material selection for Sawmill J-Bars.