What are Plastic Bateas Beams?

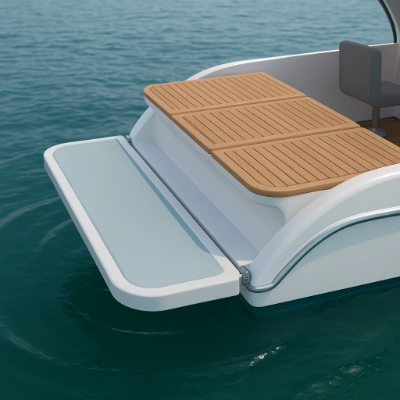

A Bateas is a floating structure for mussel farming, which have been traditionally made from wood beams where long ropes hang from them where the mussels are attached. Replacing the wood with plastics is the next step in the development of these farms.

Benefits of Plastic Bateas Beams vs wood

- Eliminate rotting – unlike wood, plastics such as Polystone 300, will not rot and degrade.

- UV & Weather Resistant – Polystone 300 has high UV resistance for long-term durability in strong sunlight.

- Non-corroding – metal fasteners will corrode in salt water, but these can be eliminated by using plastic welding to connect and build the structure.

- Low maintenance – The plastic needs no to little maintenance to keep it in good working order.

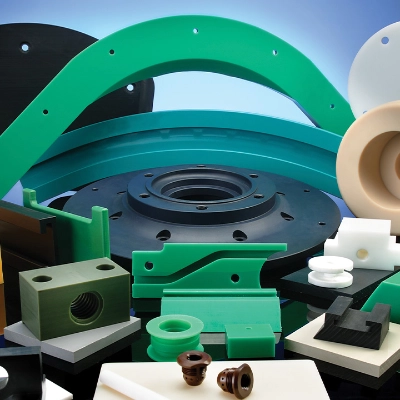

Dotmar has qualified engineers that can provide direct support with plastics for Bateas Beam material selection, as well as other aquaculture applications.

Contact us

Dotmar Engineering Plastics stands poised to address your unique challenges. Harness our expertise for bespoke engineering plastic solutions tailored to your specifications.

Insights

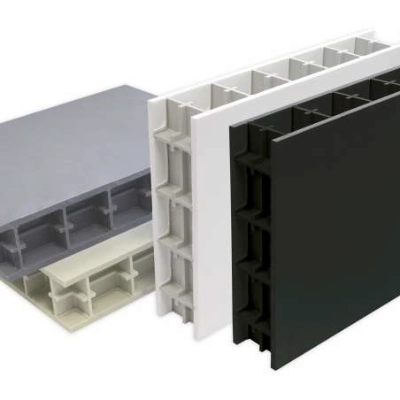

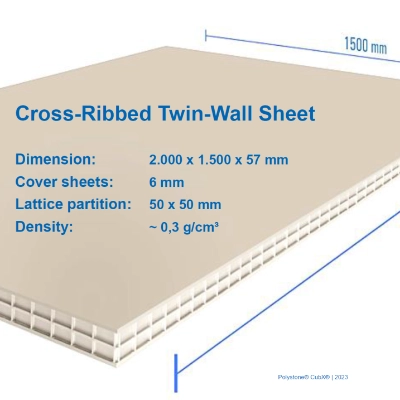

25 Nov 2024 Comparing the technical and commercial benefits of Polystone P CubX for rectangular plastic fabricated tanks and vessels

02 Sep 2024 Cooling Tunnel for Hot Filling Line

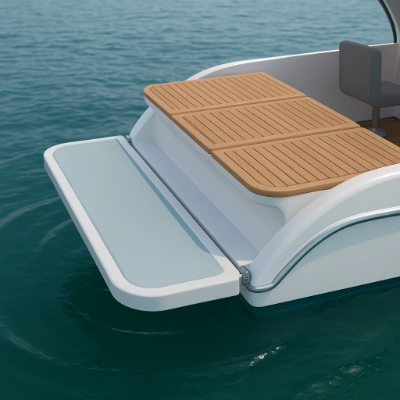

25 Nov 2024 Sentinel Boats: Pioneering Defence Durability with Polystone PG100 HDPE

03 Dec 2025 Smart Poly Trailers: Pioneering Plastic Trailers Built from Polystone 300

02 Sep 2024 Cooling Tunnel for Hot Filling Line

17 Jun 2025 Dotmar Victoria Receives PACCAR Kenworth Quality Award

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sep 2024 Plastic Abbreviations

29 Sep 2024 Plastics Properties Table

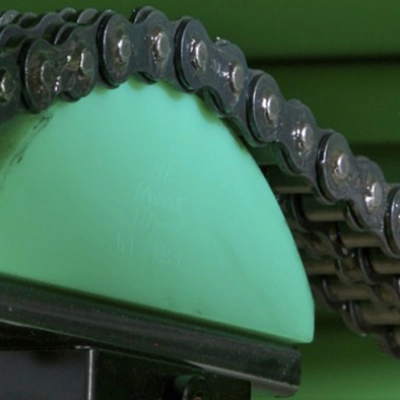

02 Sep 2024 Chain Tension-Right, or Short Chain Life

02 Sep 2024 Polystone CubX A Revolution in Rectangular Thermoplastic Tanks

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

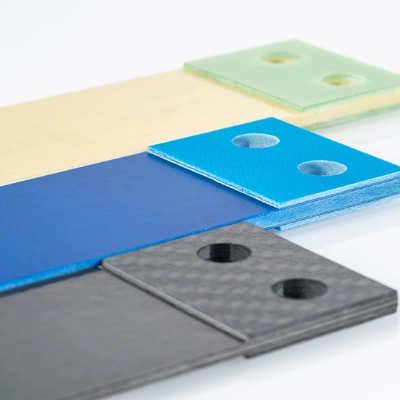

27 Sep 2024 Low Friction Wear Pads

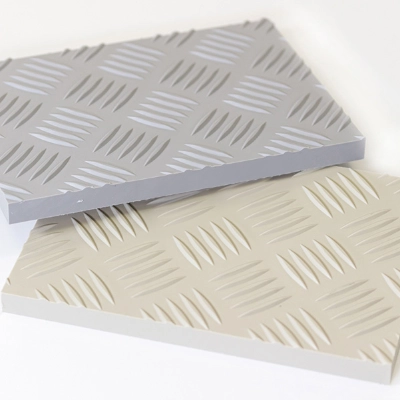

17 Jun 2025 Polystone G Checkerplate - Boat Applications

08 May 2025 Why Local Manufacturing is the Smarter Choice in 2025

07 Apr 2025 Dotmar Injection Moulding

17 Jun 2025 Dotmar Victoria Receives PACCAR Kenworth Quality Award

10 Jul 2025 Dotmar Engineering Plastics Acquires Kormax Plastics Division

04 Aug 2025 Computaleta Joins MM Plastics

01 Sep 2025

Dotmar Engineering

Plastics Expands Capabilities with Fluoro Pacific Consolidation

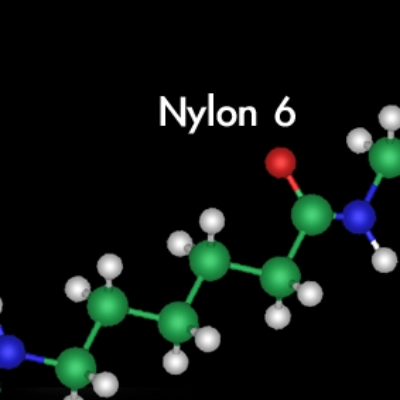

09 Feb 2025 Water Absorption of Nylons Pros, Cons and Busting Myths

14 Jan 2025 Tips for Turning and Drilling Engineering Plastics

15 Nov 2024 Significantly Reduce Your Hangup and Carryback to Optimise Your Mining Operations

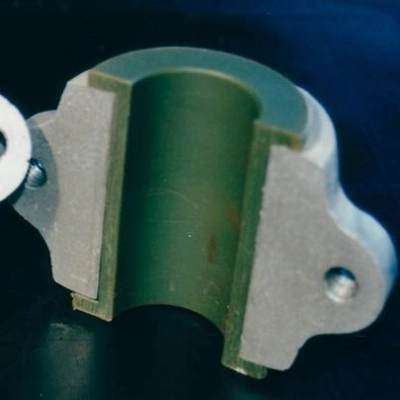

10 Oct 2024 Why use Engineering Plastic Bearings and Bushes?

29 Sep 2024 Plastic Abbreviations

29 Sep 2024 Plastics Properties Table

29 Sep 2024 Plastics Designing for Thermal Expansion

20 Oct 2024 Antistatic vs Static Dissipative Plastics

27 Sep 2024 REXNORD curve system with 1540 series MatTop

02 Sep 2024 Plastic Technical Tip-Water absorption in Nylon

02 Sep 2024 Performance Pyramid

11 Oct 2024 UHMWPE-Why Does Molecular Weight matter?

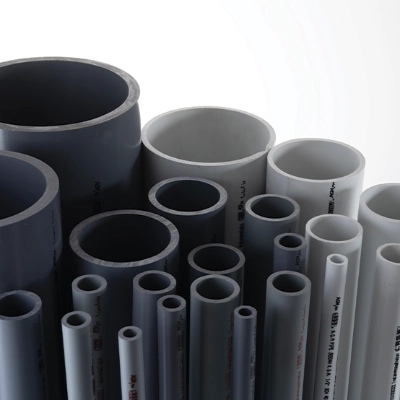

22 Jun 2025 HDPE vs PP vs PVC

03 Dec 2025 Understanding Friction in Plain Bearings and Bushes

Dual-Finish HDPE Sheet: One Surface, Two Smart Benefits

25 Nov 2024 Rochling-Reloop: Leading the Way in Sustainable Plastics

17 Jun 2025 Conveyor Products & Total Solutions for the Food and Beverage Processing & Packaging Industries

03 Dec 2024 Resistawear: Low Friction and Abrasion Resistant Tape

02 Jul 2025 Plastic Machine Guarding - Managing the Risks of Plant in the Workplace

17 Jun 2025 Polystone G Checkerplate - Boat Applications