What is a Pile Driver Cushion?

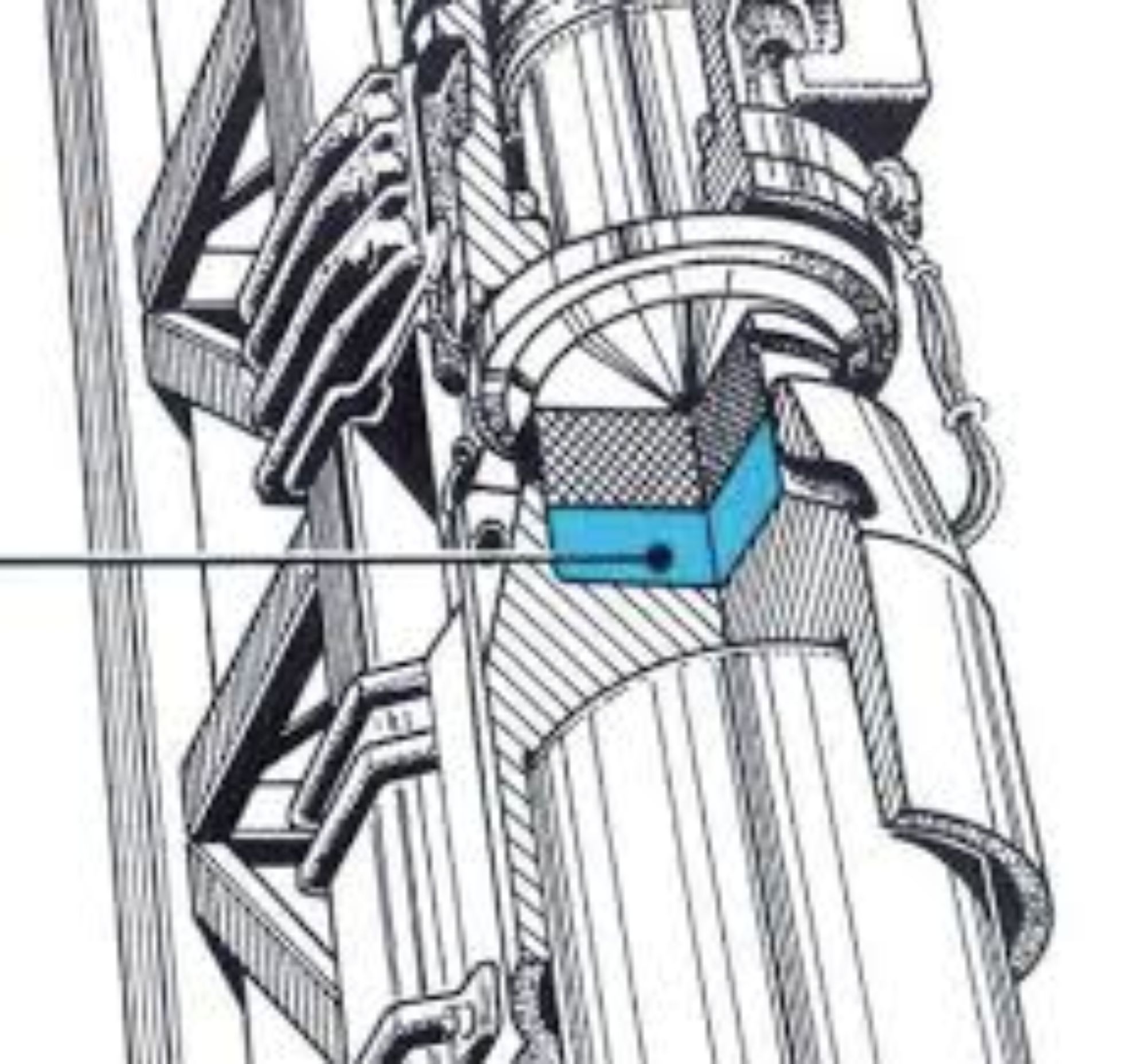

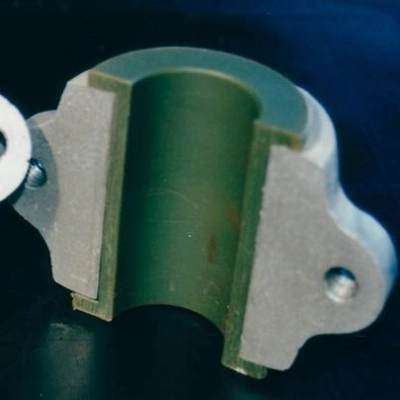

A pile driver cushion is a component used in construction for pile driving operations. It's a cushioning device positioned between the pile and the pile-driving hammer to absorb shock and prevent damage to both the pile and the hammer during the driving process.

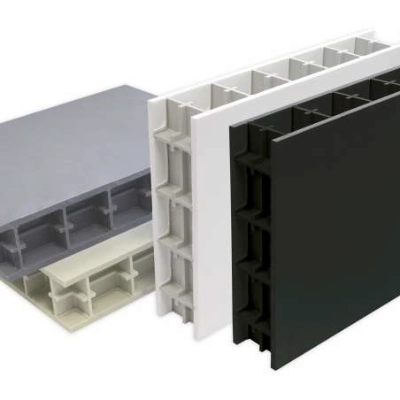

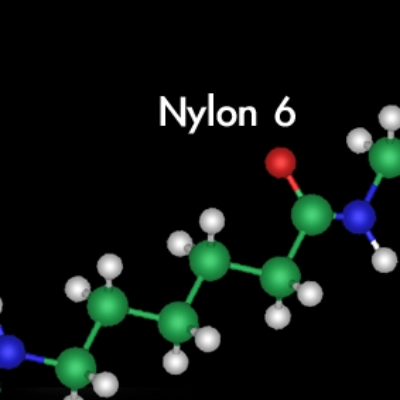

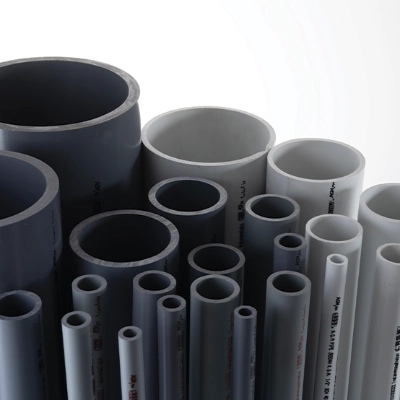

The cushion typically consists of materials like wood, metal, or plastic designed to absorb and distribute the impact force generated by the hammer. Its primary purpose is to protect the structural integrity of the pile being driven and to ensure that the force is transmitted efficiently without causing excessive stress or deformation to either the pile or the hammer.

Also referred to as Hammer Cushions, Pile Cushions, Cushion Blocks, Pile Hammer Cushion Pads and Buffer Pads.

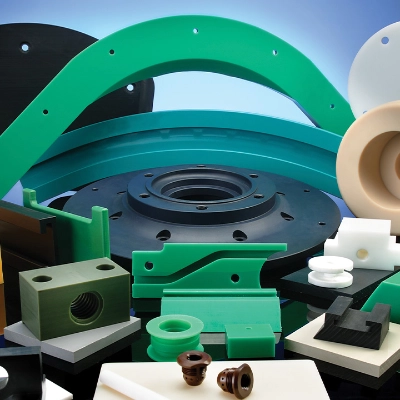

Benefits of Plastic Pile Driver Cushions

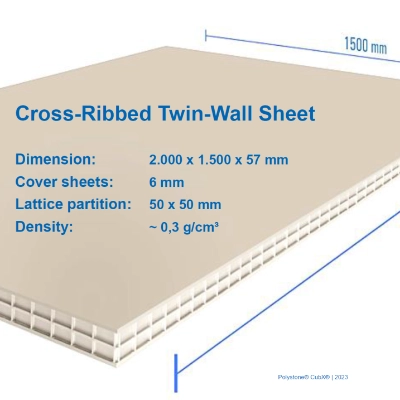

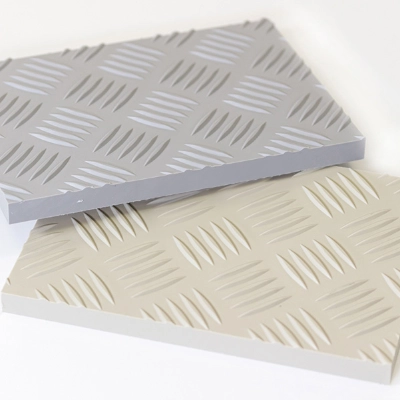

- Efficient – when the plastic is formulated from the right resins, together with the appropriate additives, the resultant properties provide good load transmission for efficient and productive driving, together with good shock absorption.

- Low Noise – particularly compared to aluminum cushions, plastics are quieter, and therefore can be used continuously in built up areas.

- Heat Resistant – Nylatron MC904P has been formulated to resist heat heating but the temperatures generated by high frequency hammer “blows”.

- Light Weight – This aids handling and transport

- Durable & resilient – Nylatron MC904P cushions are durable and resistant to wear, making them suitable for repeated use.

Dotmar has qualified engineers that can provide direct support with plastic Pile Driver Cushion sizing and configuration, which is based off decades of experience in the manufacturing of materials and designs.