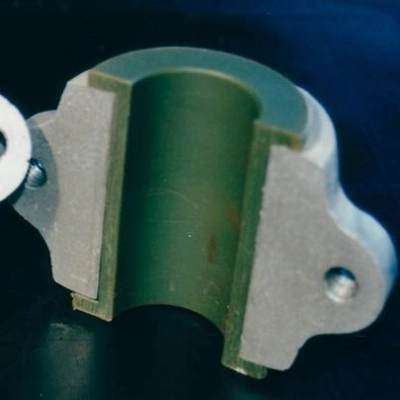

What is a Polystone Matrox Flow Promotion Liner?

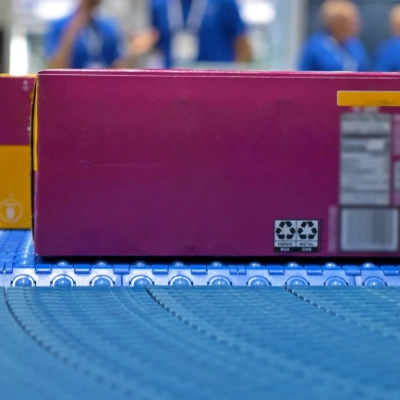

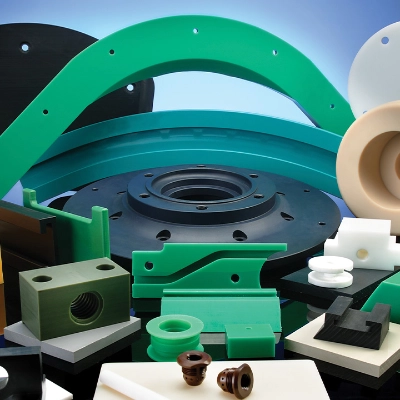

A Polystone Matrox Flow Promotion Liner is used in hoppers, chutes, trucks as well as other plants that are dealing with bulk solid materials handling. They aim to minimise bulk solid material buildup, reduce friction, and optimize the flow of materials, ultimately improving productivity and eliminating the risk of blockages or inefficiencies in the processing or transportation of bulk solid materials. They are primarily used in the mining industry, but any industry that handles bulk solid materials can benefit from Polystone Matrox Flow Promotion Linings.

Benefits of Polystone Matrox Flow Promotion Linings

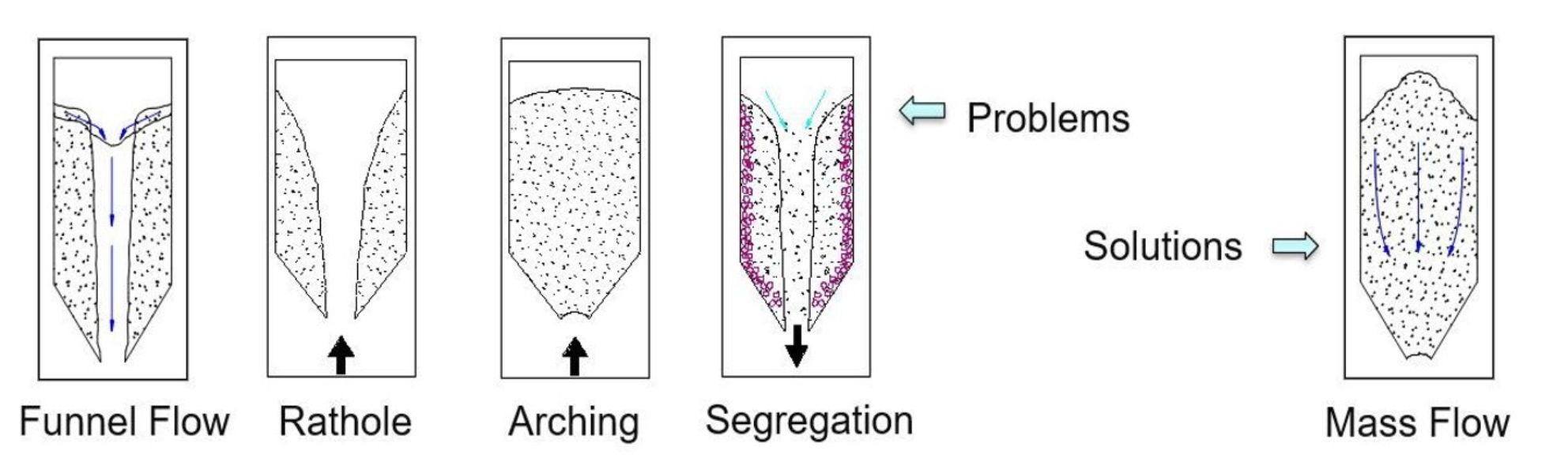

- Mass Flow – The low friction and excellent release properties promote mass flow, and therefore eliminating hang-up.

- Efficiency – Mass flow improves production throughput by eliminating poor and slow flow rates that result from hang-up.

- Safety – clearing hang-up manually can be dangerous due to putting workers in dangerous situations.

- Reduced wear – even though Polystone Matrox liners are predominantly used for flow promotion, they also provide the extra benefit of eliminating wear of the substrate.

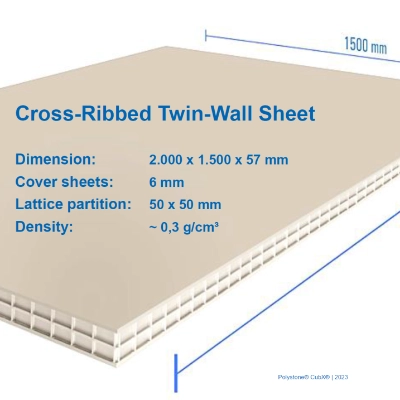

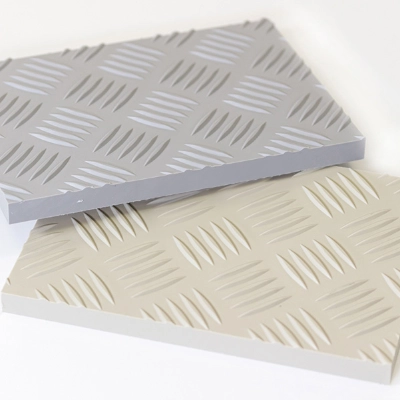

- Lightweight – With a specific gravity (density) of only 0.93 Polystone Matrox is a light weight product, therefore allowing plant to maximise their pay load.

Dotmar has qualified engineers and lining experts that can provide direct technical support on recommendations, as well as doing the full installation of the liner.

.jpg)

.jpg?w=800&h=450&crop=true)