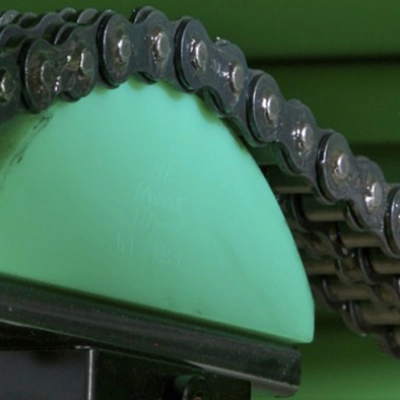

What is a Sprocket?

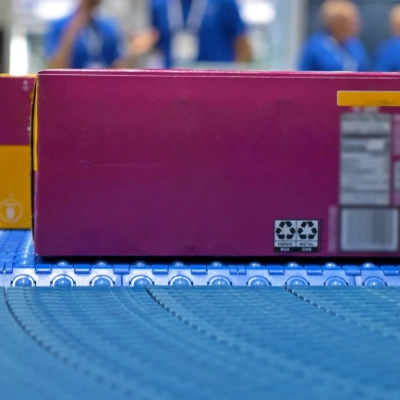

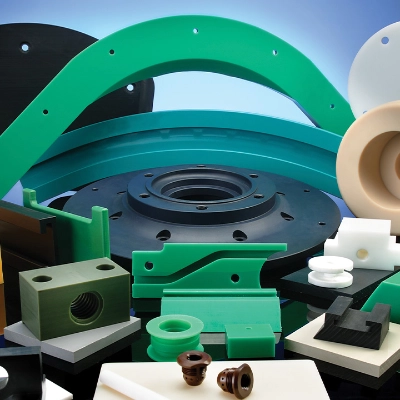

A sprocket is a toothed wheel or gear that interlocks with a chain, track, or other perforated or toothed material. It's commonly used in machinery and vehicles to transmit rotary motion between two shafts where gears are engaged with the chain, allowing the motion or power to be transferred from one part to another. Plastic sprockets are found in various applications, such as drive systems, conveyors, water treatment plants and poultry processing. They come in different sizes and tooth configurations depending on their specific use and the machinery they are part of.

Benefits of Plastic Sprockets vs metal

- Eliminating Lubricants – due to the natural lubricity of plastics and self-lubricating grades, often plastics sprockets can operate without additional external lubrication.

- Dirty & dusty conditions – plastics that have good abrasion resistance, such as Polystone 7000, Ertalon 6PLA and Ertalon LFX, are more tolerant to non-ideal operating conditions.

- Low Friction – Plastic-on-metal combinations result in low friction than metal-on-metal, and therefore low drive forces/energy.

- Reduced wear – when dissimilar materials are combined, such as plastic-on-metal, there are lower wear rates on both the plastic sprocket and metal chain.

- Lightweight – This can be advantageous in weight sensitive applications, as well as reduced energy consumption.

- Quieter Operation - Plastic sprockets will provide quieter operation compared to metal sprockets. The reduced noise can be beneficial in noise sensitive applications.

- Corrosion Resistance - Plastic sprockets are often resistant to corrosion from moisture, chemicals, and other environmental factors. This makes them ideal for use in damp or corrosive environments.

- Cost-Effective - Plastic sprockets can be more cost-effective to manufacture than metal sprockets. They can also offer cost savings in terms of reduced maintenance and longer lifespan.

Dotmar has qualified engineers that can provide direct support with plastic sprocket material selection.

.jpg)