What is an Air Scrubber?

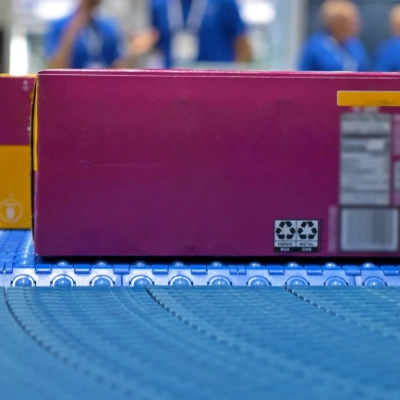

An air scrubber is a device used to improve air quality by removing contaminants or particles from the air. Mining operations often generate dust, gases, and other airborne pollutants that can be hazardous. Air scrubbers help mitigate these risks by filtering out harmful particles and pollutants from the air.

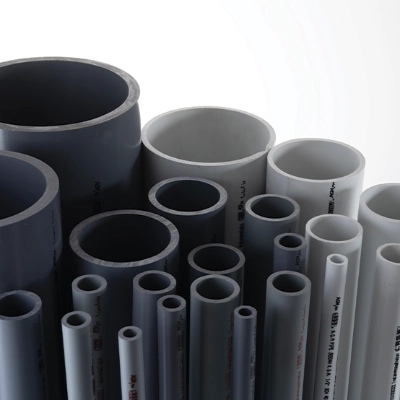

These scrubbers typically work by using various methods such as filtration, absorption, or chemical reactions to capture or neutralize pollutants. They may employ water sprays, or chemicals to trap or remove particulates, gases, or fumes from the air, depending on the specific contaminants present in the mining environment.

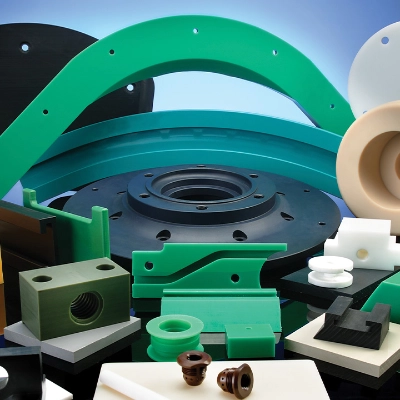

Benefits of Plastic Fabricated Air Scrubbers

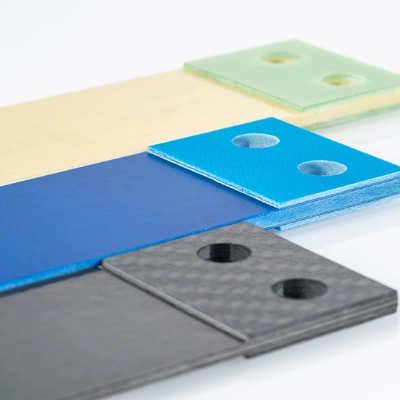

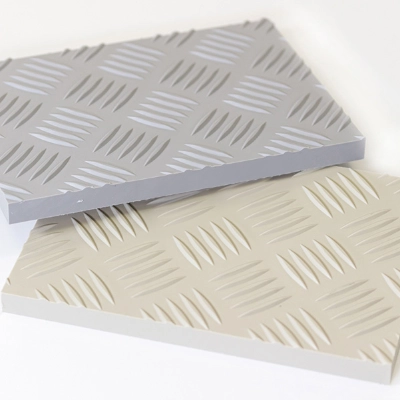

- Corrosion Resistance - Plastic air scrubbers are often more resistant to corrosion caused by harsh chemicals or environments. They can withstand exposure to various chemicals and acids present in some industrial processes, making them more durable in certain conditions compared to steel or fiberglass.

- Lightweight - Plastic scrubbers are generally lighter than steel or fiberglass, making them easier to install, transport, and handle. This can be advantageous during installation or when adjustments are necessary.

- Lower Maintenance - They often require less maintenance because they are less prone to corrosion and degradation compared to steel or fiberglass. This can result in cost savings over time due to reduced maintenance and replacement needs.

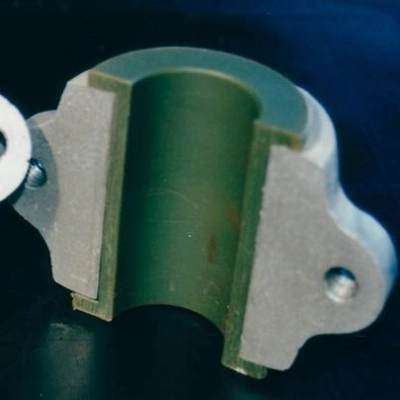

- Customisation and Design Flexibility - Plastic scrubbers can be fabricated into various shapes and designs more easily than fiberglass. This flexibility allows for custom designs tailored to specific spaces or air purification requirements.

- Insulation Properties - Certain plastics offer insulation properties that can be beneficial in maintaining temperatures or reducing condensation within the scrubber unit, which might be advantageous in particular environments.

Dotmar has qualified engineers that can provide direct support with plastic material selection for air scrubbers.