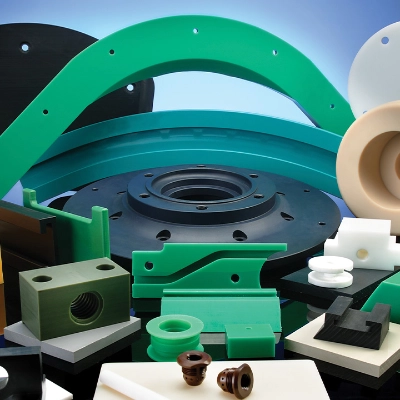

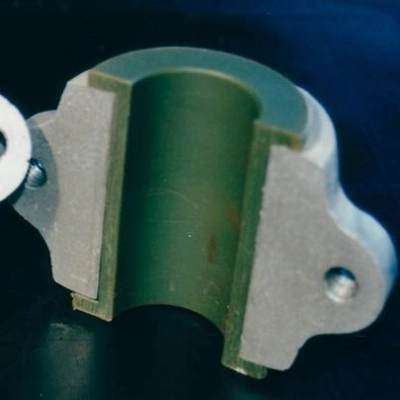

What is a Screw Conveyor Liner?

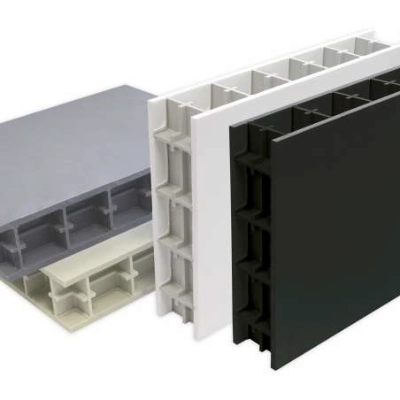

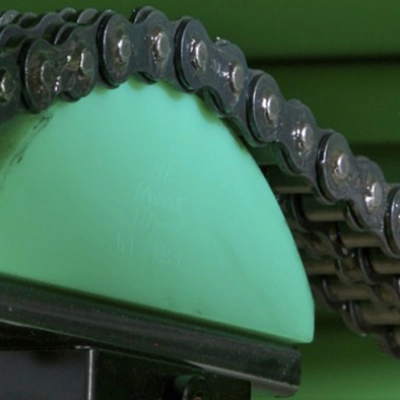

A screw conveyor liner is a protective layer used inside a screw conveyor to prevent wear and tear caused by the movement of materials being conveyed and/or a low friction material for the screw to run on. These liners are typically made from various materials such as plastic, polyurethane, or other abrasion-resistant substances. The primary purpose of a screw conveyor liner is to extend the life of the conveyor by shielding it from the abrasive effects of the materials being transported and/or the screw itself. The liner also helps in reducing friction, minimizing material buildup, and improving the overall efficiency of the conveyor system.

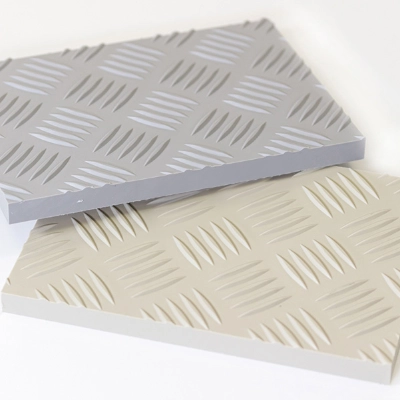

Benefits of Polystone 7000 Screw Conveyor liners

- Abrasion Resistance: Polystone 7000 is highly resistant to abrasion, extending the service life of the screw conveyor.

- Chemical Resistance: It resists corrosion and is chemically inert, making it ideal for conveying a wide range of substances, including corrosive materials or those with varying pH levels.

- Low Friction: Polystone 7000 has a low coefficient of friction, reducing the energy required for material movement and lowering power consumption.

- Non-Stick Properties: Materials often don't adhere to Polystone 7000, reducing the likelihood of build-up or blockages along the conveyor, which can hamper efficiency.

- Ease of Maintenance: Due to its non-stick properties, it's easier to clean and maintain the conveyor system, reducing downtime for cleaning procedures.

- Noise Reduction: The low friction characteristics of Polystone 7000 liners can contribute to quieter operation compared to metal liners.

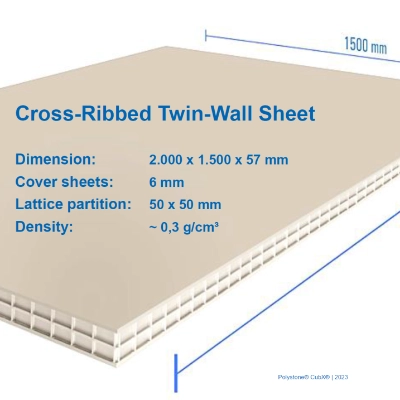

- Lightweight: Polyethylene is lighter than many metals, which can ease installation and reduce the load on the conveyor system.

Dotmar has qualified engineers that can provide direct support with the selection of the correct grade of Polystone for Screw Conveyor Liners.

%20-%20cropped.jpg?w=800&h=450&crop=true)