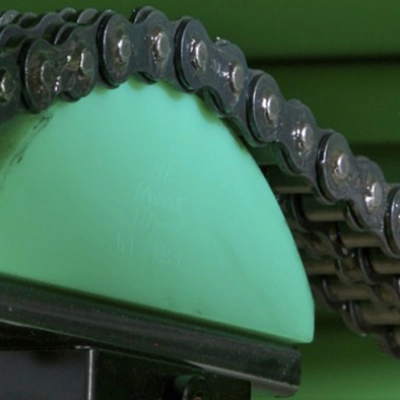

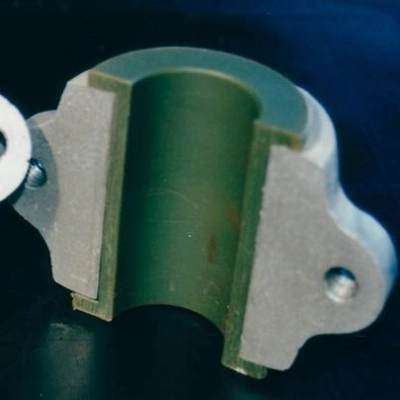

What is a Plastic Sheave or Pulley?

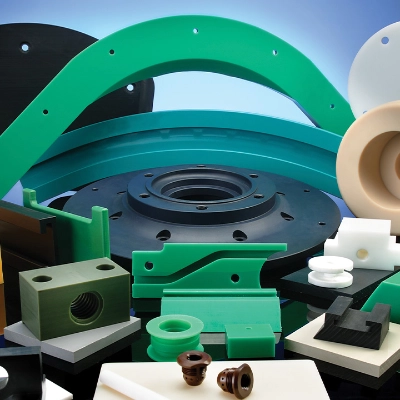

A sheave or pulley is a grooved wheel on an axle, used to support movement and redirect the force applied to or by a rope, cable, or belt. They're often made of metal or plastic and can be used individually or in combination with other sheaves to create a mechanical. They are commonly found in various applications, like elevators, cranes, forklifts, stacker and reclaimers for the mining resource industry, as well as conveyors.

Benefits of Plastic Sheaves and Pulleys vs Metal

- Service Life of Wire Ropes – Wire ropes tend to last 2-6 times longer when operating on plastic. This is due to the lower friction levels, as well as better elasticity that creates an increase in surface contact, therefore reducing contact pressures.

- Service Life of Wire Rope Sheaves – Plastic Wire rope Sheaves tend to last 2-3 times longer than steel sheaves as plastic-on-metal wear rates are lower that metal-on-metal.

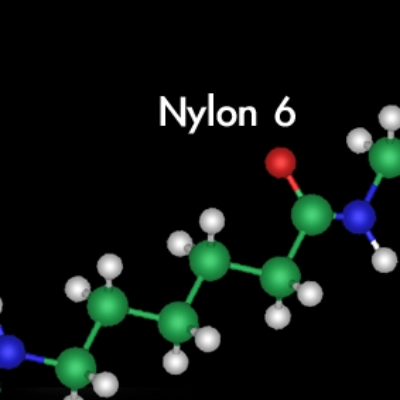

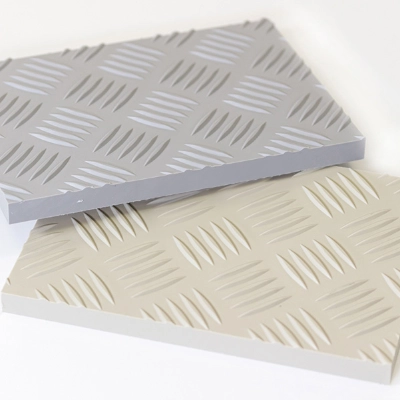

- Light Weight – Plastics such as Ertalon 6PLA and Nylatron GSM (which are the most commonly used) are 1/7 the weight of steel. Apart contributing to increased lifting capacity, the lower weight reduces in lower inertia forces, and therefore reduced slippage in operation, contributing to lower wear rates.

- Non-Corrosive – The lack of corrosion compared to steel means that the surface finish does not deteriorate, therefore contributing to improved wire rope life.

Dotmar has qualified engineers that can provide direct support with plastic sheave and pulley designs, including conducting calculations.