UNIBOARD

Uniboard is a very simple product to fabricate and work with. Its unique construction ensures fabrication, which includes routing, drilling, biscuit joining, screwing and gluing is not only a task for professional fabricators, shop fitters and joiners but also the weekend warrior building a cubby house for the kids or kennel for the dog.

Uniboard marine ply replacement materials are low weight, very low moisture absorption, high mechanical strength, chemical resistance and machinability allow this product to be used across a wide range of timber replacement applications including for acoustic sheet.

This material is perfect for the following applications;

- Outdoor furniture

- Outdoor kitchens/BBQ areas

- Cabinets, storage units and shelving

- Equine stables, wash down bays and pool surrounds

- Soccer and other sports activities as Hi-impact fencing panels

- Zoological applications

- Rural applications such as Farms, dairies and horse studs as a timber replacement product

- Garden panels

- Freeway decoration panels

- Marine and aquatic applications

- Retail stands

- Building site formwork

- Caravan & 4WD lining

Sheet size

Standard Uniboard size: 2440 x 1220

Sheet thickness and weights

| Thickness | Weight |

| 10mm | 19-20kg |

| 12mm | 23-24kg |

| 15mm | 28-30kg |

| 19mm | 37-38kg |

Uniboard Benefits

- Lightweight

- Zero moisture absorption

- Excellent impact resistance

- Excellent weatherability

- Abrasion resistance

- Coloured throughout the entire sheet

- Reduced maintenance

- Easily cleaned

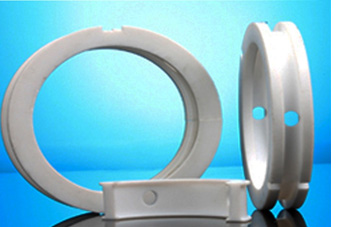

Nylon Wire Rope Sheaves

- Rope life 2-6 times longer

- Sheave life 2-3 times longer

- No corrosion

- Lightweight

- Templates

- Can operate without roller bearing

- Longer life

- Reduced life

- Easy to replace

- The right elasticity

- Shorter pilling tile - less energy loss

PTFE

- Bridge pot bearings

- Bridge structural bearings

- Bridge bearing strips

- PTFE slide bearings

- PTFE lined pipe and fittings

The current methods for producing wine are far away from those used by our ancestors. Nowadays, derived from complex and costly technical studies, meticulous systems of detailed care are carried out regarding the soil, the plant, the fruit, and of course, its transformation in wine in order to obtain the best quality.

But for all these, it is essential a conveying and handling aseptic system for cooling the grapes, selecting them, and carrying them to the destemmer with the care and asepsis required by the most demanding quality control.

Our modular belts have been carrying out this task in this selective industry successfully for some years, so that they are installed in the most famous wineries.

E50 – Flat Top E50 – Flush Grid E50 – Flush Grid B50 – Flat Top B50 – Flat Top